Nov 7 2025

The Lowdown on the Range Chart

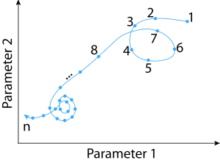

To use in-process measurements for quality control 100 years ago, Walter Shewhart proposed the \bar{X}-\sigma charts. It entailed arranging workpieces in rational subgroups, summarizing measurements by subgroup into means and standard deviations, charting both, and checking new values against control limits.

When Harold Dodge tried to implement the \bar{X}-\sigma charts at Western Electric, the engineers balked at calculating sample standard deviations with paper, pencils, and slide rules. To gain acceptance, Dodge let them use sample ranges and plot them in R charts instead. While easier to understand and to use daily, sample ranges are mathematically more complex and more sensitive to extreme values than standard deviations.

The SPC literature glosses over the motivation for the R chart and its math. It provides recipes for using these charts, but no explanation. We shouldn’t ask manufacturing professionals to use a tool without explaining its purpose and its theory. This is what this post is trying to remedy.

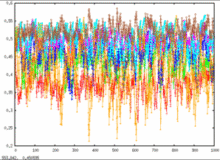

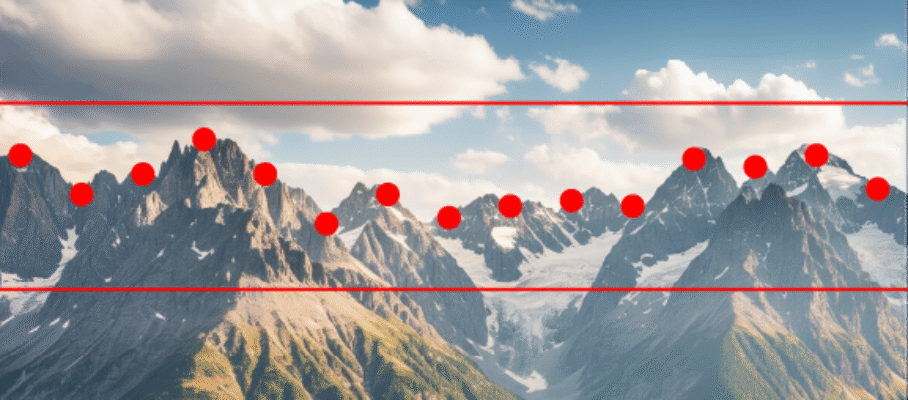

Like all control charts, the R chart uses limits calculated for the Gaussian distribution. As no simple formula is available for the R chart, setting control limits for it requires numerical approximations that must have consumed months for human computers in 1924. Today, you can replicate them instantaneously with software. These calculations reveal that the \pm 3\sigma limits in the books for the range chart do not actually encompass the 99.73% of the distribution that they do in \bar{X} charts.

The R chart was an ingenious workaround to technical and human constraints of the 1920s that no longer exist. Today, rather than blindly applying these tools, we must draw inspiration from their inventors and develop solutions to meet the process capability challenges we are actually facing.

Dec 13 2025

Gemini Deep Research About Michel Baudin

Share this:

Like this:

By Michel Baudin • Management 1 • Tags: AI, Assembly, data science, Gemini Deep Research, industrial engineering, Logistics, Manufacturing