Oct 28 2017

Objections To The History Of Quality As Told On The ASQ Website

5 years ago, I pointed out several omissions in the ASQ’s History of Quality pages, which have not been corrected. Specifically, I faulted them for ignoring the TPS/Lean approach to quality, the role of interchangeable parts technology, and the Roman philosopher Cicero, who coined the word “quality.” The first page, however, also contains what I think is an error of commission, where it credits the guilds of medieval Europe as precursors in the field, as follows:

“From the end of the 13th century to the early 19th century, craftsmen across medieval Europe were organized into unions called guilds. These guilds were responsible for developing strict rules for product and service quality. Inspection committees enforced the rules by marking flawless goods with a special mark or symbol.[…] Inspection marks and master-craftsmen marks served as proof of quality for customers throughout medieval Europe. This approach to manufacturing quality was dominant until the Industrial Revolution in the early 19th century.”

Feb 11 2019

Seeing Germany’s factories | Kazuo Kumabe | May, 1936

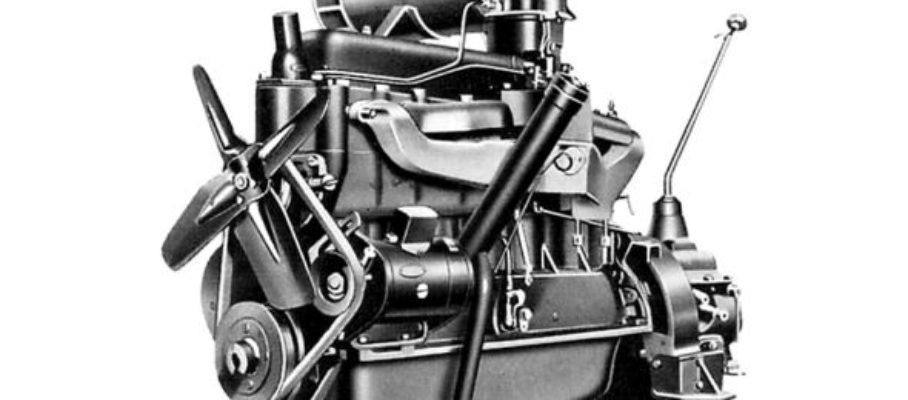

The author, Kazuo Kumabe was a classmate of Kiichiro Toyoda at Tokyo Imperial University and a researcher on car engines, who was involved with R&D for Toyota from 1936 to the early 1950s. The German influence on Toyota’s product technology and design can be traced to him.

In 1936, he was instrumental in bringing a DKW car to Japan and disassembling it. Today, the DKW brand lives on as Audi. In 1947, Kumabe we the was the chief designer of the SA, Toyota’s first post-war model, inspired by the Volkswagen Beetle several years before high-volume production actually started on the beetle. Kumabe wrote this article for the Machine and Electricity magazine (Kikai oyobi Denki, 機械及び電気) in May, 1936 as a summary of a tour of German factories in late 1935.

It’s brief and does not go into any of the details of what he learned. It does not even give the dates of this trip.

Continue reading…

Contents

Share this:

Like this:

By Michel Baudin • History • 7 • Tags: German factories, Kazuo Kumabe, Kiichiro Toyoda, Toyota