Dec 13 2025

Gemini Deep Research About Michel Baudin

The article below was generated by Gemini Deep Research, now based on Gemini 3, in response to the following prompt:

“Gather all the stuff you can about Michel Baudin and tell me what are the strengths and weaknesses of his work.”

The inspiration was Bob Emiliani, who has done the same. It is as complete and accurate as you might expect from a human journalist, and better than anything I have seen from other AI tools. In particular, it doesn’t credit me with books I haven’t written, degrees I don’t have, jobs I never held, or the wrong ethnic background. Still, it’s not perfect, and I have picked a few nits, mostly with numbers:

- In Section 2.1, it confuses the time I worked in research with the period during which my results were published. In 1981-1986, I worked as an engineer in semiconductors, while my papers based on earlier work made their way through peer-review.

- In 2.4, it says I have lived in the US for 31 years. It’s actually 45 years.

- In 2.4, it reduces the influence of the various cultures I have immersed myself in to a single phrase for each, which is nonsense.

- In 3, it says I have written four books, and then includes paragraphs discussing each of my five books.

- Section 3 describes all of my books as being in the “nuts and bolts” series. In fact, it is only three of them: Lean Assembly (2002), Lean Logistics (2005) and Working with Machines (2007). The other two, Manufacturing Systems Analysis (1990) and Introduction to Manufacturing (2023) are not part of this series.

Section 7.2 lists the weaknesses of my work. The first is that my work “is not for the faint of heart. It is dense, mathematical, and dry.” Each of my books aims to serve the needs of a specific audience, from developers of production planning & scheduling systems to designers and managers of assembly operations, supply chain managers, designers and managers of processes involving people working with machines, or students of industrial engineering and operations management. I haven’t yet written one for C-suite executives, but my next collaboration with Torbjørn Netland might be suitable for them.

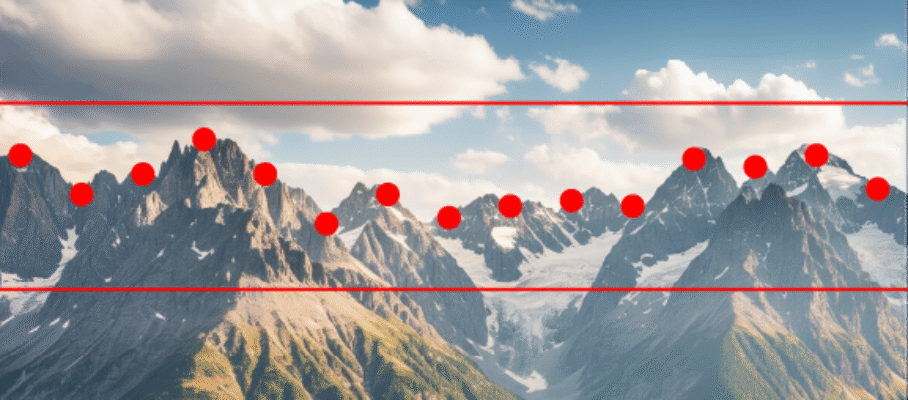

There is much more math in my blog posts than in my books or in my consulting practice. There is a constituency for it, in professionals who are unhappy applying formulas handed to them that they don’t understand. To my surprise, the math I include in my posts elicits reactions, comments, and sometimes corrections. One reader on LinkedIn once commented that I “make the esoteric understandable.” As for being dry, I try not to be, by including many real examples and illustrations.

The second weakness is my “grumpy expert” persona. When participating in forums on social media, you want respectful but spirited debates to engage readers. Calling people names or attributing motives turns readers off, but challenging claims and ideas is productive. When they are inconsistent with my experience, I ask for elaboration, clarification, and corroboration. People with valid points provide them, and maybe I should thank them more profusely for it.

The third is “niche focus.” My niche is manufacturing, which accounts for ~10% of GDP in the US, the UK, France, and Italy, and ~20% in Germany and Japan. It’s kept me busy. When I am done solving manufacturing problems, I may look into healthcare, software, or service industries. It will never happen.

But enough of my reactions to the output from Gemini Deep Research. Here is what it says:

Dec 22 2025

Three San Francisco Bay Area Writers Have Coffee

When Katie Anderson, Olivier Larue and I met last Thursday, what did we discuss? We started with the pros and cons of self-publishing versus going through established publishing houses. Then we talked about the challenges and opportunities of providing books in various media. We discussed Olivier’s two new books and, finally, our kids. Katie has the youngest ones; I have the oldest.

Share this:

Like this:

By Michel Baudin • News 3 • Tags: Lean, Manufacturing, Publishing, Toyota