Apr 1 2014

Steve Jobs on Juran | Curious Cat | John Hunter

See on Scoop.it – lean manufacturing

“This webcast shows an interesting interview with Steve Jobs when he was with NeXT computer. He discusses quality, business and the experience of working with Dr. Juran at NeXT computer. The video is likely from around 1991.”

The interview starts slowly, with Jobs collecting his thoughts before speaking, and it was not supposed to be about Juran. Jobs is the one who brings up Juran in response to a question about quality.

At first, he reverently calls him “Dr. Juran” — Juran was not a PhD — and then, affectionately, “Joe Juran.” Steve Jobs as the respectful disciple is something I had not seen before. What was he so impressed with? Here are a few I picked up in the video:

- While focused on quality, Juran did not see it as more than it was. It is about making good products and services; it is not a philosophy of life.

- For all his accomplishments, Juran remained simple. He treated everybody alike, and answered every question put to him as if it were the most important in the world.

- Juran was “driven by his heart” to share what he had learned and found out in decades of work.

Towards the end of the video, the 30-year old Jobs sounds more and more as if he setting a role model for himself. But Juran lived to be 103; Jobs died at 56, only three years after Juran, and did not get the chance.

Apr 3 2014

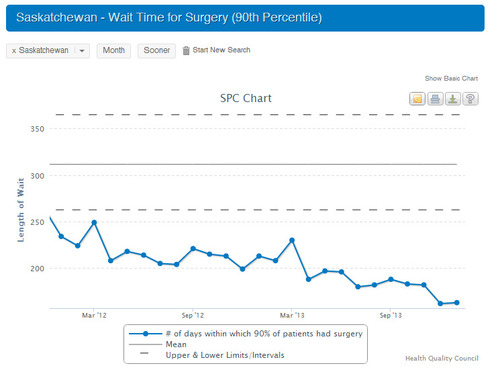

Saskatchewan Health Care Data Not Showing Improvements from Lean?

See on Scoop.it – lean manufacturing

“[…]The government has stated that its kaizan promotion offices do not measure or evaluate lean, and that no reports have been written. At the same time, however, it has stated that lean has already demonstrated benefits. To test this, I reviewed the HQC website – Quality Insight – that has a significant amount of provincial data. For each indicator I will report the first and last month or year where data were collected.[…]”

“[…]The government has stated that its kaizan promotion offices do not measure or evaluate lean, and that no reports have been written. At the same time, however, it has stated that lean has already demonstrated benefits. To test this, I reviewed the HQC website – Quality Insight – that has a significant amount of provincial data. For each indicator I will report the first and last month or year where data were collected.[…]”

The article’s author, Mark Lemstra, from The StarPhoenix, claims that Lean yielded no improvement in the financial or medical performance of Saskatchewan’s health care system, based on data from the Health Quality Council (HQC).

The article’s title is only about “Savings,” but most of the body is about health outcomes and perceptions, and presented through numbers buried in text.

Before taking this article at face value, I recommend checking out the HQC website directly. As in the featured image above, some metrics have clearly improved. Other indicators are flat, like the willingness of patients to recommend their hospital, or the rate of medical error reports. And some have moved in the wrong direction, such as those related to pain management.

It is perhaps not the rosy pictures that the Lean boosters would like, but neither is it the disaster Lemstra is painting.

See on www.thestarphoenix.com

Share this:

Like this:

By Michel Baudin • Press clippings 0 • Tags: Health care, Lean, Saskatchewan