Jul 18 2022

The Most Basic Problem in Quality

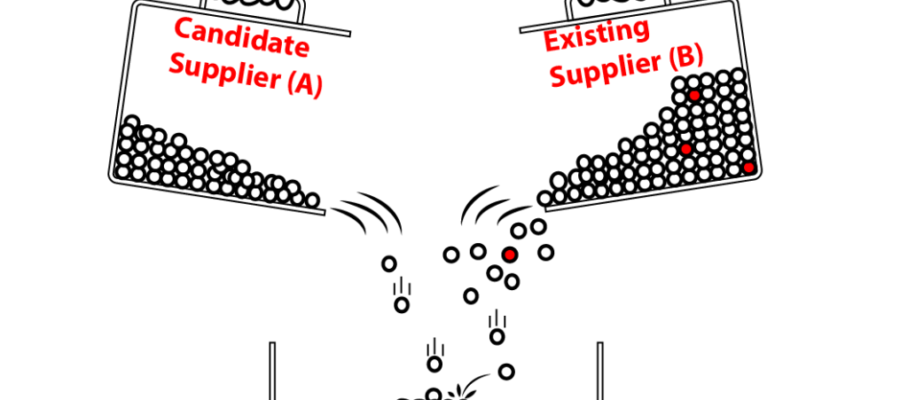

Two groups of parts are supposed to be identical in quality: they have the same item number and are made to the same specs, at different times in the same production lines, at the same time in different lines, or by different suppliers.

One group may be larger than the other, and both may contain defectives. Is the difference in fraction defectives between the two groups a fluctuation or does it have a cause you need to investigate? It’s as basic a question as it gets, but it’s a real problem, with solutions that aren’t quite as obvious as one might expect. We review several methods that have evolved over the years with information technology.

Oct 12 2022

Musings on Large Numbers

Anyone who has taken an introductory course in probability, or even SPC, has heard of the law of large numbers. It’s a powerful result from probability theory, and, perhaps, the most widely used. Wikipedia starts the article on this topic with a statement that is free of any caveat or restrictions:

This is how the literature describes it and most professionals understand it. Buried in the fine print within the Wikipedia article, however, you find conditions for this law to apply. First, we discuss the differences between sample averages and expected values, both of which we often call “mean.” Then we consider applications of the law of large numbers in cases ranging from SPC to statistical physics. Finally, we zoom in on a simple case, the Cauchy distribution. It easily emerges from experimental data, and the Law of Large Numbers does not apply to it.

Contents

Share this:

Like this:

By Michel Baudin • Laws of nature 1