Nov 7 2022

Analyzing Variation with Histograms, KDE, and the Bootstrap

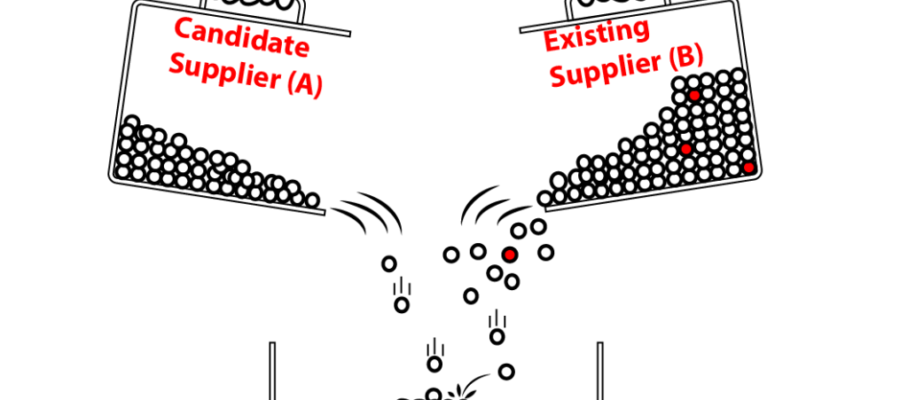

Assume you have a dataset that is a clean sample of a measured variable. It could be a critical dimension of a product, delivery lead times from a supplier, or environmental characteristics like temperature and humidity. How do you make it talk about the variable’s distribution? This post explores this challenge in the simple case of 1-dimensional data. I have used methods from histograms to KDE and the Bootstrap, varying in vintage from the 1890s to the 1980s:

Other methods were surely invented for the same purpose between 1895 and 1960 or since 1979, that I don’t know about or haven’t used. Readers are welcome to point them out.

The ones discussed here are not black boxes, automatically producing answers from a stream of data. All require a human to tune the settings of the tools. And this human needs to know the back story of the data.

Nov 12 2022

Automation and People

This is the first in a series of posts about learnings from the Van of Nerds tour of 11 manufacturing sites in Northern France completed on September 9. First, I describe who we are, why and how we went on this tour. Then, to make this post more than just an introduction, I appended a summary of our observations on automation and people. There is more to come.

Share this:

Like this:

By Michel Baudin • Van of Nerds 6 • Tags: Automation, I4.0, Industry 4.0, Information technology, IT, jidoka, Lean, Operational Technoloy, OT