Sep 13 2013

A defense of old-fashioned WIP accumulation | Manufacturing Digital

See on Scoop.it – lean manufacturing

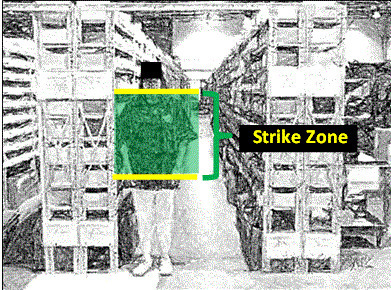

The gist of this article is that you should hold just enough WIP to meet your production requirements with the changeover times you currently have and protect your bottlenecks against malfunction in other resources. So far, this is stating the obvious, and a visit to a Toyota plant or even dealership is enough to see that the Toyota system is not one with zero inventory. You see shelves of stampings, bins of bolts, and trees of wire harnesses. The Kanban system involves some inventory, and, in fact, the only approach that doesn’t is just-in-sequence. What is considered waste is not all inventory, but unnecessary inventory, accumulated for no valid reason anyone can explain.

The article, however, goes further and asserts that it is cheaper to accumulate WIP than to expose and solve the problems that make it necessary, which is a return to the mass-production thinking that was prevalent in pre-Lean operations management.

What the Lean successes of the past decades have shown is (1) that the overall costs of WIP were understated and (2) that the ingenuity of production people and engineer was underestimated. You operate today and next week with the resources that you have, dysfunctional as they may be, and you hold WIP as needed to sustain production. As you do this, however, as an organization, you keep working at solving your problems so that you need less and less WIP month by month and quarter by quarter. This perspective is missing from the article.

See on www.manufacturingdigital.com

Sep 15 2013

The Economist gets Lean wrong

See on Scoop.it – lean manufacturing

“Lean production is the name given to a group of highly efficient manufacturing techniques developed (mainly by large Japanese companies) in the 1980s and early[…] When a lean-production system is first introduced, stoppages generally increase while problems are ironed out.”

“Lean production is the name given to a group of highly efficient manufacturing techniques developed (mainly by large Japanese companies) in the 1980s and early[…] When a lean-production system is first introduced, stoppages generally increase while problems are ironed out.”

The Economist is a British magazine not known for getting facts wrong, but it did here.

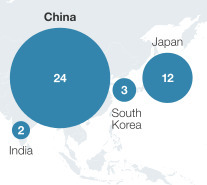

Lean Production is not for the 1980s. The name may be from the late 1980s but the thing itself is a work in progress that started decades earlier. And it is from Toyota, not from generic “large Japanese companies.”

And a competent implementation does not start by making things worse.

See on www.economist.com

Share this:

Like this:

By Michel Baudin • Press clippings 0 • Tags: Lean Production, Toyota, Toyota Production System