Feb 24 2012

Bodo Wiegand on Shop Floor Management as Leadership Responsibility

Bodo Wiegand heads the Lean Management Institute, which is the German affiliate of the Lean Enterprise Institute. The following is a translation from German of a large excerpt from his February, 2012 newsletter, Wiegand’s Watch:

Last week I was invited to a visit a company to discuss the benefits of Lean management with its Board. On such occasions I always ask for a detailed factory tour first. This way, the discussion can be better focused on the company’s actual problems and not get stuck in theory.My short audit begins before the actual visit. Before turning into the visitor parking lot, I drive around the facility to inspect the grounds. Is it tidy? What do I see? As there marked pathways? How much material lying around? How many employees, forklifts, trucks and cars are moving around? This is my very first impression.In the actual plant tour, I know they will not show me the problem areas of the company, and that they will keep me as much as possible on a visitor path is. However, by saying that I would like to go from customer to supplier, I usually get to see what I need. So we follow the value stream from back to front.The way to Shipping usually reinforces what I have seen outside: if it is messy outside, with no marked pathways or areas are selected, heaps of materials are piling up, and cars and trucks randomly parked, what else can I expect in production?Far too few pay attention and remember that this is the company’s calling card.Now, in this case are with me the production manager and the Lean Leader. They explain with pride that they have been doing Lean for two years already for 2 years and have achieved huge success. They have set-up times in half on several machines. But we were at Shipping and I just wanted to know what products were arriving today to go out today or tomorrow at the latest. After questioning the Shipping clerk then we found that two containers that were very important and urgent were just too late.To my question on how often something like this happens, the production manager answered “Rarely”; the shipping clerk, “Every day.” After a short discussion, the production manager admitted to a delivery reliability of 80%, but he was not quite sure. To my question about lead time the Lean leader proudly answered “In general, about 3 weeks.”“How long does it take to run through a super hot job” , I asked as a follow-up.“2 days,” he shot back.My next question about how many projects he had initiated to reduce the lead time demotivated further, as he had to admit there weren’t any.Well, for me the lead time is one of the most important metrics in a company is and a priority in the execution of projects. The shorter the lead time, the higher the flexibility, the smaller the stocks, the more stable the process, the less time available to make mistakes, and the more efficient the organization.But satisfaction with a lead time ratio of 1 to 10 between hot and normal jobs in German companies is quite amazing. For the hot job to be completed in 2 days, it flows through the company without intermediate storage, is processed immediately and is carried through without pause, without waste, except of course that the supervisor personally takes the matter in hand. But why is it not always like this for all jobs? Why is the exception and not the rule?But we moved on. In assembly, the Lean leader explains that they have built up an assembly line, but that it still cannot work to the takt time, and that they have therefore built up behind the line an assembly rework shop for quality problems.Hello? – Has he really understood Lean?But even outside of the assembly line you could not overlook the signs of chaos. You saw pallets with several items pulled from the supermarket, but by the pallet-load rather than in the quantities necessary for assembly. The reason was simple. The storage space in the supermarket was insufficient and the supermarket was just too full.The degree of Lean manufacturing and Lean understanding was close to zero.Next, I turned my attention to the order fulfillment process. But there, also, they had no clue where to start with takt time, bottlenecks, and inventory. The information boards were full of outdated figures on revenue and absenteeism. Two departments were reasonably tidy and provided with standards that were not followed. Brooms and tools had assigned shadows, but were not actually available. Employees were running around for no apparent reason, or talking in small groups. The production manager didn’t know the supervisor’s name, the clocks were off, some windows broken and lamps without bulbs, etc., etc.[…]To avoid any misunderstanding, as I walk through a company, I don’t pretend to understand everything, but I try to get an overall impression. Those of you who walk through production daily must know how to see and should focus their attention on a different theme every day to be a good shop floor manager. But beware! It is a difficult, thorny path – but it’s worth it.

Feb 26 2012

Growth in Maintenance’s Share of Manufacturing Employment

Via Scoop.it – lean manufacturing

This article describes a method involving initial testing and extensive training used by an Alabama steel mill to increase Maintenance’s share of its work force to almost 30%.

Jim Peck drew my attention to it on NWLEAN through a post in which he questioned their approach to recruitment as training people who didn’t need it or turning down people with the right skills. This kind of information, of course, is not in the article.

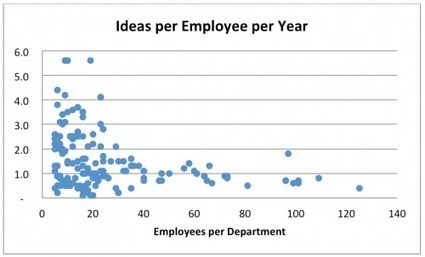

The article points out the growing of share of Maintenance in the work people do in a manufacturing operation as it evolves. Based on the numbers in the article, close to one in four employees of the mill works in Maintenance today, and they are trying to increase this ratio. Steel is an industry that has had enormous productivity increases in the past decades. As they point out in the article, they went from 45,000 employees in the 1940s to 2,100 today, who produce as much.

In today’s labor-intensive manufacturing activities, maintenance’s share of the labor force is on the order of 5%, and I believe we can expect that number to rise. For example, an auto plant that employs 5,000 today may produce the same amount with the same depth of manufacturing with 500 people 25 years from now — if cars are still around in 2037… And, out of these 500 people, 150 to 200 will be in Maintenance, the rest being primarily programmers of automatic machines.

Whether testing is appropriate or not depends on the relevance of what people are tested on. An organization has the right to decide what “qualified” means for its own needs. On the other hand, I find testing inappropriate if there is a hidden agenda.

Many Silicon Valley software companies, for example, subject applicants to “coding interviews,” in which they are tested on such topics as the details of sorting algorithms. A computer science student learns this in college but rarely uses it as a professional programmer, because 90% of the time you need to sort records, you just invoke a sort function without worrying about what is under the hood. As a consequence, this kind of test is an effective way to bias the interviews in favor of recent college graduates and filter the experienced programmers.

Via www.reliableplant.com

Share this:

Like this:

By Michel Baudin • Blog clippings 0 • Tags: Maintenance, Management, Manufacturing