Jun 6 2014

Next frontiers for lean | McKinsey

See on Scoop.it – lean manufacturing

“…Quietly, though, in Nagoya, Japan, Taiichi Ohno and his engineering colleagues at Toyota were perfecting what they came to call the Toyota production system, which we now know as lean production. Initially, lean was best known in the West by its tools: for example, kaizen workshops, where frontline workers solve knotty problems; kanban, the scheduling system for just-in-time production; and the andon cord, which, when pulled by any worker, causes a production line to stop…”

This article implies that the “Kaizen workshop” is a tool of the Toyota Production System, when in fact it is an American invention from the 1990s and what it does is not what is meant by Kaizen in Japan

Then the article describes Kanban as “the scheduling system for just-in-time production.” It is really only a a tool of scheduling among many, including heijunka, just-in-sequence, consignment… The last example, Andon cords, had been observed at Ford in 1931.

Even if this choice of examples is unfortunate, Toyota people invented many tools while adopting and refining existing ones, and it is true that each tool, taken out of context, is of limited value. Toyota’s merit is to have deployed them in a uniquely effective way as part of a system of production.

This is, however, not what the article says. It jumps instead to management disciplines, like “putting customers first,” an idea that bazaar merchants worldwide have had for millenia.

“Enabling workers to contribute to their fullest potential” and “constantly searching for better ways of working” is in fact something that Toyota has done better than its competitors. And these are sound management objectives, but you could pursue them and still not be competitive.

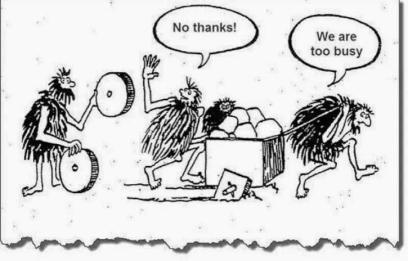

The article implies that the technical content of the Toyota production system is a detail. All that matters is focusing on customers and treating people right. Is it? I don’t think so.

This attitude is the root cause of the failure of so many “Lean implementations.” Until the technical content of the Toyota Production System is understood and properly valued, the Lean movement cannot claim “Mission Accomplished” in manufacturing.

See on www.mckinsey.com

Jun 23 2014

Ex-Toyota exec preaches production gospel to aspiring supplier | Automotive News

Source: www.autonews.com

This article paints a picture of what implementing Lean is really all about. It starts from the business needs of a parts supplier to the household appliance industry that wants to move into auto parts, where tolerances are tighter.And implementation is centered around what Lillard calls giving the plant “a little TLC.”

According to the article, her first task was “to ask employees to write and create step-by-step instructions on how to do their jobs.” This is a far cry from all the nonsense about starting with 5S. It does not require value-stream maps, and it cannot be done in so-called “Kaizen events.”

Instead, it is patient work that requires time and perseverance.There is a TPS twist on work instructions — using A3 sheets posted above workstations rather than 3-ring binders on shelves — but such instructions have been recognized as essential since the 19th century, and have been part of the industrial engineering curriculum since its inception, decades before Toyota was started.

Yet, the article implies that a stamping parts manufacturer in the American Midwest survived for 70 years without them. Having seen many plants with non-existent or ineffective job instructions, I believe it, and it raises many questions.

Share this:

Like this:

By Michel Baudin • Press clippings 2 • Tags: Automotive, TPS, Work instructions