Jan 2 2014

Lean and Management Processes

An online sparring partner of 15 years, Bill Waddell, concluded our latest exchange with the following:

“Lean is comprised of three elements: Culture, management processes and tools. While you obviously have a keen awareness of the culture and tools, you continually under-appreciate the management processes, Michael.”

It is a 3-step progression: first, Bill makes a general statement of what Lean is, then he points out a serious shortcoming in my thinking, and finally he misspells my name.

As I am not trying to go global cosmic with Lean but instead remain focused on Manufacturing, rather than Bill’s three elements, I see Lean as having the four dimensions identified by Crispin Vincenti-Brown. Whatever you do has some content in each of the following:

- Engineering, in the design, implementation, and troubleshooting of production lines.

- Logistics and Production Control, covering both physical distribution and the processing of all information related to types and quantities of materials and good.

- Organization and People, covering the structure, sizing, responsibilities and modes of interaction of departments in production and support, to run daily operations, respond to emergencies, and improve.

- Metrics and Accountability. How results are measured and how these measurements are used.

Attention must be appropriately balanced in all of these dimensions and, if one is under-appreciated in the US, it is Engineering, not Management. Metrics and organization issues hog the attention; what little is left over goes towards Logistics and Production Control, and Engineering is taken for granted. The tail is wagging the dog, and reality bites back in the form of implementation failures.

What is a management process, and how does it differ from a tool? The term sounds like standard management speak, but, if you google it, the only unqualified reference to it that comes up is in Wikipedia, where it is defined as “a process of planning and controlling the organizing and leading execution of any type of activity.”

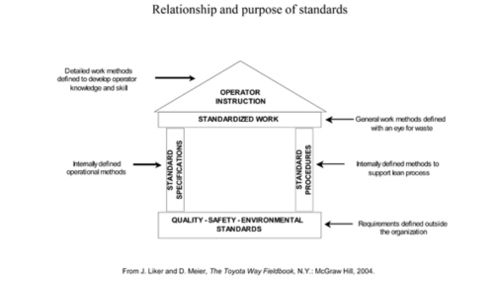

Since Henri Fayol, however, we have all been taught that the job of all managers is to plan, organize, control, and lead. In those terms, there doesn’t seem to be any difference between a “management process” and just “management.” All other Google responses are for the processes of managing different functions, like the “Project Management Process,” “Performance Management Process,” “Change Management Process,” or the “A3 Management Process.” The corresponding images are a variety of box-and-arrow diagrams, pyramids, wheel charts, dish charts, and waterfalls/swim lanes, as in the following examples:

A manufacturing process is the network of tasks to make a product from materials — with routes that merge, branch, and sometimes even loop. A business process, likewise, is a network of tasks to turn inputs into outputs, like the order fulfillment process that turns customer orders into deliveries. A political process is also a network of tasks leading to a particular result, like the election of a president or the approval of a budget. So, what about a management process? And what is the level of appreciation that it deserves?

Bill is the one who should really explain it, but, if I were to use this term, at the most basic level it would be for what I have been calling protocols, by which I mean the part of management work that is done by applying sets of rules or procedures rather than making judgement calls. They are pre-planned responses to events that might occur but are not part of routine operations. It can be the arrival of a new member into a team, the failure of a truck to show up, or a quality emergency.

This is the spirit of Toyota’s Change Point Management (CPM), in which the pre-planned responses are prepared by the teams that are potentially affected by the events and posted in the team’s work place. When the event occurs. all you have to do is retrieve the plan and you know what to do. And it is usually a better plan than what you would have improvised in the heat of the moment.

At a higher level, I would call process a protocol used to organize the way you make judgment calls. You can’t set the strategy of a company by applying rules, but you can use Hoshin Planning to organize the way you do it. A process like Hoshin Planning is akin to the rules of a game; it doesn’t determine how well the managers play. If they just comply with a mandate and go through the motions, they will produce a certain result. If, on the other hand, they understand what they are doing, connect it to their own work, and see the value in it, then they will produce a different result.

A good process does not guarantee a good outcome, and great teams have been able to coax performance out of dysfunctional processes. What is the proper level of appreciation for these management processes? Clearly, there is more to management than processes, and the best managers are those who excel at endeavors for which there is no script.

I learned to appreciate the relationship between management and engineering in Manufacturing from working with my mentor, Kei Abe. When he took me on as a junior partner in 1987, one of the first things I learned from him was to approach problems in a holistic manner, simultaneously at the technical and the managerial levels. I saw him coach a shop floor team on the details of SMED in the morning, and the board of directors on company strategy in the afternoon. It’s not a common mix of skills, but I believe it is what a manufacturing consultant should have.

Jan 23 2014

The NUMMI Story (Minus the Ending) | Matthew May

See on Scoop.it – lean manufacturing

“At the risk of being repetitive, allow me to retell one of my favorite stories. First, imagine the worst place you’ve ever worked. The darkest, most depressing, soul-sucking work environment you’ve ever had the misfortune to inhabit.

“At the risk of being repetitive, allow me to retell one of my favorite stories. First, imagine the worst place you’ve ever worked. The darkest, most depressing, soul-sucking work environment you’ve ever had the misfortune to inhabit.

Got it in your mind’s eye? Now, multiply it by oh, say, 100. That’s how bad the place I’m about to describe was. I know, because I spoke to people who were there.

The year was 1982. It was the year of Jordaache Jeans. The year of Wendy’s “Where The Beef?” commercial. And the It was 1982, the first full year of Reaganomics.

The place was the General Motors Fremont, California plant…”

The NUMMI joint venture between GM and Toyota is a great story of thorough transformation. It is how a car plant from worst to best. Unfortunately, it ended in 2010, when GM when bankrupt and Toyota declined to take over the entire venture.

Now Toyota is part owner of Tesla, the facility is the Tesla plant, and it has been getting renewed attention as such. This is a new lease on life but Tesla’s 10,000 cars/year do not compare with the 250,000 NUMMI used to make.

See on matthewemay.com

Share this:

Like this:

By Michel Baudin • Blog clippings 0 • Tags: GM, Lean, NUMMI, Toyota, TPS