May 13 2014

The GM Toyota Rating Scale | Bill Waddell

See on Scoop.it – lean manufacturing

“In a survey of suppliers on their working relationships with the six major U.S. auto makers – Toyota, Honda, Nissan, Ford, Chrysler and GM – GM scored the worst. But of course they did. They are GM and we can always count on such results from them. […] Toyota scored highest with a ranking of 318, followed by Honda at 295, Nissan at 273, Ford at 267, Chrysler at 245, with GM trotting along behind the rest with an embarrassing 244.”

While I am not overly surprised at the outcome, I am concerned about the analysis method. The scores are weighted counts of subjective assessments, with people being asked to rate, for example, the “Supplier-Company overall working relationship” or “Suppliers’ opportunity to make acceptable returns over the long term.”

This is not exactly like the length of a rod after cutting or the sales of Model X last month. There is no objective yardstick, and two individuals might rate the same company behavior differently.

It is not overly difficult to think of more objective metrics, such as, for example, the “divorce rate” within a supplier network. What is the rate at which existing suppliers disappear from the network and others come in? The friction within a given Supplier-Customer relationship could be assessed from the number of incidents like the customer paying late or the supplier missing deliveries…

Such data is more challenging to collect, but supports more solid inferences than opinions.

See on www.idatix.com

May 16 2014

Does the World Need More MBAs? | Sally Blount says “Yes” | Business Week

See on Scoop.it – lean manufacturing

“Business is our most important social institution—improving the lives of millions. Yet it falls far short of its potential to serve society […] When you’re creating the next Google, Tencent, or Apple, you’re going to need people with the training, skills, and network that business education is uniquely good at providing. There’s a reason all of those companies hire people with MBAs. Even more important than the skills argument, however, is the intellectual argument for an MBA education, where there is critical knowledge to be gained. Business has evolved to be the dominant social institution of our age. Business is the cultural, organizational, and economic superforce in human development.”

“Business is our most important social institution—improving the lives of millions. Yet it falls far short of its potential to serve society […] When you’re creating the next Google, Tencent, or Apple, you’re going to need people with the training, skills, and network that business education is uniquely good at providing. There’s a reason all of those companies hire people with MBAs. Even more important than the skills argument, however, is the intellectual argument for an MBA education, where there is critical knowledge to be gained. Business has evolved to be the dominant social institution of our age. Business is the cultural, organizational, and economic superforce in human development.”

Bill Waddell disagrees. I do too, for different reasons.

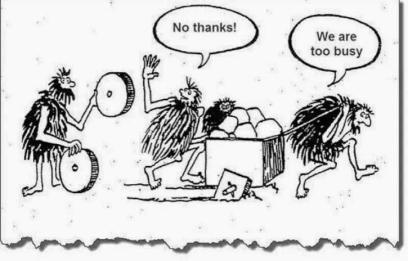

While I agree with Blount about the value of business skills, I see MBA programs as steeped in the druckerian fallacy that management is a profession in its own right, like Medicine or Engineering, and that a well-trained manager can be equally effective at running businesses in any industry, whether selling sugared water or making computers that change the world.

Rather than being a specialty in its own right, “Business Administration” is best viewed as a set of skills that complements industry-specific knowledge and experience.

That business is “the cultural, organizational, and economic superforce in human development” is something the dean of a business school would say. You could easily make the case for other forms of human endeavors, like universal public education, scientific research, or even democracy.

Bill Waddell seems to think that MBAs are inherently unable to implement and sustain Lean. I have, however, met several leaders who excelled at Lean while having MBAs. But it was not all they had.

A unique feature of this degree is that it takes over the identity of its holders, to the point that they describe themselves as “being MBAs” rather than “having MBAs.” The ones I have admired for their excellence in Lean had an engineering degree and had worked as engineers before getting MBAs.

See on www.businessweek.com

Share this:

Like this:

By Michel Baudin • Press clippings 1 • Tags: Lean, MBA, Peter Drucker