Dec 1 2011

Steven Spear on Problem-Solving with JIT: Not Bad for an Academic Paper

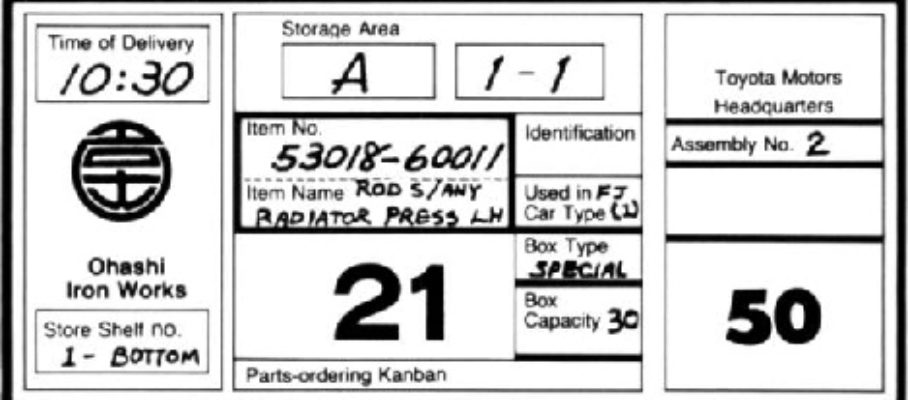

Steven Spear’s The Essence of Just-in-Time:Imbedding diagnostic tests in work-systems to achieve operational excellence is a working paper from Harvard Business School in 2002 focused on the interaction between JIT and problem-solving. It is an important topic, only briefly alluded to in Lean Logistics and covered in more detail in When to Use Statistics, One-Piece Flow, or Mistake-Proofing to Improve Quality, but there are many other improvement opportunities besides product quality, and shining a light on their relationship with JIT is useful.

Spear’s paper is worth reading because he did his homework: it is based on research that involved immersion in a Toyota supplier support team, visits to seven Toyota plants and 12 suppliers in Japan and the US, and working as an assembler in a non-Toyota plant for comparison. I recommend in particular sections 4 to 7. Section 4 is a case study of mattress manufacturing at Aisin Seiki, from which the following sections draw general conclusions.

You have to look past the other sections, which mainly reflect Spear’s membership in the academia tribe. His research is described as an “ethnographic study,” which conjures up the image of an American or European spending 15 years among the Guaranis of Paraguay recording what they are willing to share of their language and culture. That this vocabulary should be used in a study of Lean reflects how alien the world of manufacturing is to academia.

As an academic, Spear is obligated to reference other academics, but not non-members of the tribe, no matter how major their contributions. For example, the only Japanese author in the bibliography is Takahiro Fujimoto, from the University of Tokyo, but neither Taiichi Ohno nor Shigeo Shingo appear. Section 3, on Methods, opens with “Many scholars argue…” With all due respect, the arguments of scholars don’t amount to a hill of beans in Manufacturing, because, unlike Computer Science or Biology, it is not a field to which they have contributed much. From Taylor and Gastev to Ohno and Shingo, the key innovators in Manufacturing have almost all been self-taught, Lillian Gilbreth being the exception with a PhD. Why was Spear’s research not done in an Industrial Engineering department, where its content would normally place it? As I found in my own ethnographic studies of academia, the need for grants pushes researchers in other directions, like genetic algorithms.

Dec 1 2011

Railway Gazette: Russian Railways looks lean

Via Scoop.it – lean manufacturing

RUSSIA: Alstom Transport is to provide Russian Railways specialists with training in the implementation of lean manufacturing technology under a memorandum of co-operation which was signed during the Second Railway Congress in Moscow on November 19.

Via www.railwaygazette.com

Share this:

Like this:

By Michel Baudin • Press clippings 0 • Tags: Lean manufacturing