Aug 27 2021

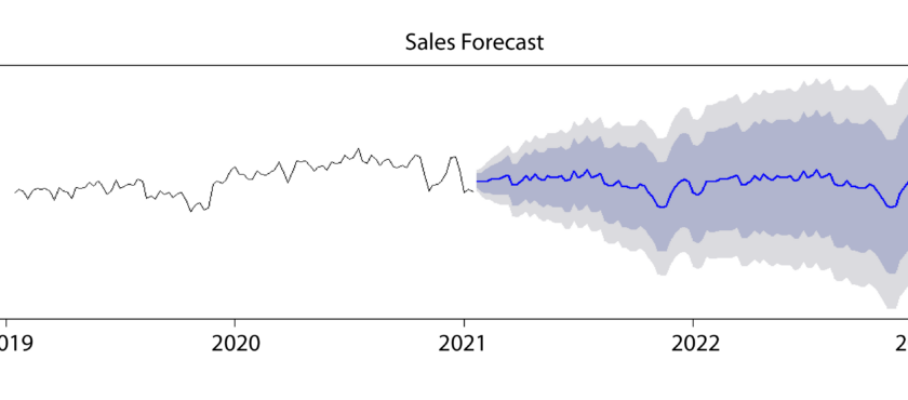

Sales Forecasts – Part 3. Generating Probability Forecasts

My last two long posts were about evaluating sales forecasts. They begged the question of how you generate these forecasts. This is a partial answer, about what you can tell from a history of sales through both classical methods and recent developments, particularly probability forecasting.

Aug 29 2021

Distributed Teams Can Work After All

The 2012 paper in Science about the CRISPR/Cas9 system has been hailed as the greatest breakthrough in biology since Crick and Watson’s discovery of the DNA double helix in 1953. It has earned its two Principal Investigators (PI), Emmanuelle Charpentier and Jennifer Doudna, the 2020 Nobel prize in chemistry. Laypersons cannot really follow this paper but what we can better understand is how the research team worked. And it is remarkable.

Share this:

Like this:

By Michel Baudin • Management 1 • Tags: Project management, Team