Jan 26 2013

5S in Sri Lanka: Passing fad or firm philosophy? | The Sundaytimes Sri Lanka

See on Scoop.it – lean manufacturing

Over the past few years, Sri Lanka has seen a tremendous increase in the application of the Japanese workplace organization method, the 5S system, particularly

A well-written, warts-and-all account of a development I was not aware of. The last paragraph says: “…those companies which have succeeded in embracing it as a philosophy have benefited in numerous ways, financially and non-financially…” And this is as specific as it gets.

See on www.sundaytimes.lk

Jan 29 2013

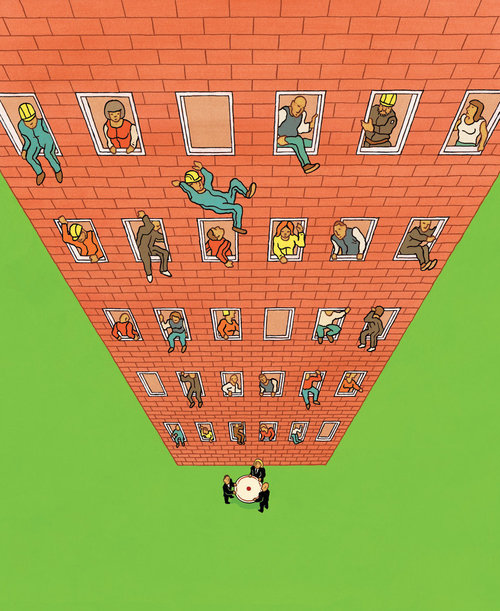

Unions, Lean, and Manufacturing Jobs | New York Times

See on Scoop.it – lean manufacturing

The article sounds right about unions in the US, but incorrectly describes France as having “drastically higher union coverage.” French unions barely represent 8% of the work force, not much more than the 7% in the US, but they do keep a high profile, with more than 90% of their funds coming, in various forms, from the government. Their financing was exposed in early 2012 by a parliamentary commission report that was first quashed and then leaked to the press (http://bit.ly/WdL1lk).

See on www.nytimes.com

Share this:

Like this:

By Michel Baudin • Press clippings 0 • Tags: Lean, Manufacturing, Union