Jun 30 2016

Hardship Accounting Of Jobs

France is implementing a new law requiring “hardship accounting,” for the purpose of giving special pension benefits to employees whose jobs impose physical, environmental and rhythm constraints beyond a given threshold in 10 categories. This is causing a dispute between employers, who balk at the detailed record keeping required, and the government, which insists that a duly voted law must be obeyed. What I find disturbing in this tug-of-war is that I hear no voice saying that the existence of hardship jobs is abnormal and that they should be eliminated. Giving special treatment to the holders of these jobs is better than nothing, but it is an immediate countermeasure, not a long-term solution.

Jan 13 2020

The Engineering of Human Work

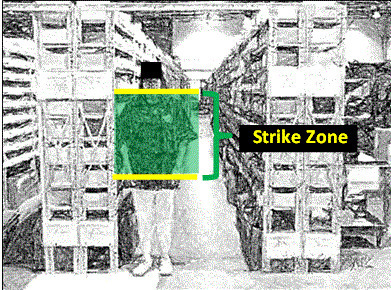

“Human work engineering” is neither a major in any university nor a job title I have ever encountered. As a specialty, it would integrate content currently filed under Human Factors, Ergonomics, Safety, Human-Machine Interfaces, Usability Engineering, Mistake-Proofing, and Jidoka into a consistent approach to production and service delivery.

But wait! Isn’t it what Industrial Engineering (IE) was supposed to be?

Continue reading…

Contents

Share this:

Like this:

By Michel Baudin • Training • 3 • Tags: Engineering, Ergonomics, Human Work, IE, industrial engineering, Management, Mistake-Profing, Usability Engineering