Jan 31 2013

David Meier on Productivity Metrics | The Lean Edge

See on Scoop.it – lean manufacturing

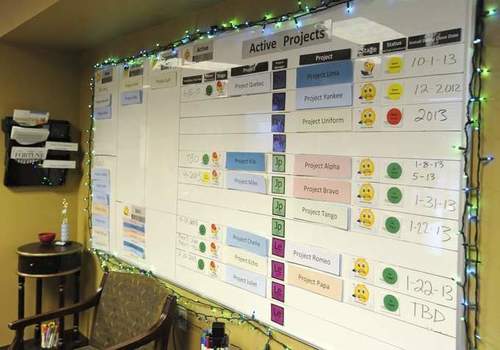

“The first point I want to make is that any measure has flaws and will not completely reflect reality. They should be considered indicators and in some way all refer to some sort of “standard” or desired condition. This is the basis for problem identification, which is the main purpose.

Any measure is a ‘snapshot’ of conditions during a specific time period and reflects many variables that are occurring. Some measures such as productivity are based on assumptions such as standard hours. The notion of standard hours is flawed in many ways that I won’t get into, but this measure can be used effectively (if used carefully). The mistake that is often made is to evaluate performance based on the measure and to drive inappropriate behaviors like overproduction.”

Insights on productivity metrics used at Toyota.

See on theleanedge.org

Feb 1 2013

Russian translation of Comparing Lean, TQM, Six Sigma, “and related enterprise process improvement methods” | Вестник Лин

See on Scoop.it – lean manufacturing

Недавно в рекомендованных материалах сайта Scoop.It! я нашел ссылку на статью Киркора Боздогана из подразделения проектирования систем Массачусетского технологического института, датированную маем 2010 г. и озаглавленную «Движение к интеграции системы Лин, Всеобщего менеджмента качества, Шесть сигма и других сходных методов совершенствования процесса на предприятии»…

If you prefer to read in Russian, this is the translation of my post on MIT article comparing Lean, TQM, Six Sigma, “and related enterprise process improvement methods”

Если вы предпочитаете читать по русски, это перевод моего поста по английски.

See on www.leanforum.ru

Share this:

Like this:

By Michel Baudin • Blog clippings 0 • Tags: Agile, BPR. BPM, Lean, MIT, Six Sigma, TOC, TQC, TQM