Oct 6 2013

Predicting the benefits of “Lean Actions”

In the TPS + 1 ENGINEERING group on LinkedIn, Hela Hassine asked “How can we predict and quantify the profit of lean actions before implementing them?”

I see three types of what Hela Hassine call “actions”:

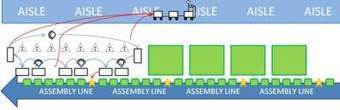

- For some, you can do a complete discounted cash flow analysis before implementing. Cellularizing a job-shop falls into this category.

- For others, you cannot calculate the benefits ahead of time, but you can measure them afterwards. When you improve quality, first you can’t tell ahead of time by how much it will actually improve, and second, you can’t tell how much good this improvement will do to your business. After you have improved quality, you know by how much, and you can also measure the market impact of the improved quality, which is its dominant benefit. There is no way you can justify quality improvement ahead of time through cost-of-quality analysis.

- For the rest, the benefits are too diffuse to be measurable. 5S falls is in this category.

This has obvious consequences on implementation sequencing, that are often overlooked. Projects that lend themselves to a-priori justification are easiest to sell to management, and success in such projects gives you the credibility you need to undertake others with less tangible benefits. In other words, you are better off starting with cells than with 5S.

Oct 12 2018

For Lean Production to Work, a Company Needs to Be All In | Ellen Rosen | The New York Times

“For a company in Chesterfield, Mo., it involved something as seemingly simple as attaching a trash can to an employee’s chair. For one in St. Louis, it meant leaving the cover off an electronic temperature controller. For others it’s meant gathering employees from the chief executive on down for what’s known as Kaizen events — based on the Japanese word for continuing improvement. What do these seemingly unconnected efforts have in common? They are approaches to what is known as lean manufacturing — or, more recently, lean production — aimed at streamlining production processes, enhancing employee engagement and increasing profits.”

Source: The New York Times(10/11/2018)

Michel Baudin‘s comments: Thanks to Kevin Hop for drawing my attention to this article. Like him, I do read The New York Times regularly and usually appreciate the quality of its reporting. This article, however, does not measure up. It reflects the conventional wisdom on Lean manufacturing which, if anything, explains why so many implementations fail.

Share this:

Like this:

By Michel Baudin • Press clippings 2 • Tags: Cellular manufacturing, industrial engineering, Lean, Manufacturing engineering, process engineering, Production Engineering, Toyota, TPS