May 30 2013

Ohno Disciple Led Earthquake Recovery in Semiconductor Plant| The Truth About Cars

See on Scoop.it – lean manufacturing

“After the March 11 monster earthquake and tsunami wiped out large parts of Japan, headlines focused on the near-meltdown of Fukushima. Recently, I learned that there was a strong likelihood of a worldwide economic meltdown, caused by a microchip factory 80 miles south of Fukushima. Here is the story of how the crisis was contained.

‘I was already retired when the earthquake came,’ remembers a Toyota official who requested that his name is not published. He is a seasoned production expert, one of the few alive who received personal training from Taiichi Ohno, the father of the Toyota production system. ‘I thought, let others handle the problem, but I was wrong.’ He was recalled and asked to spearhead the Toyota part of the reconstruction effort.”

While critics have often claimed that low inventories made Lean supply chains vulnerable to natural disasters, Toyota’s record in actual events says otherwise, in cases including, in the US, the Mississippi flood of 1993 and, in Japan, the Aisin Seiki fire of 1997 and now the Fukushima earhquake of 2011.

As it turns out, the combination of vigilance in logistics and relationships that make it possible to enlist the supply chain in rapid recovery works better than inventory. In the case of the Fukushima earthquake, more inventory would simply have meant more losses.

See on www.thetruthaboutcars.com

May 31 2013

Using videos to improve operations | Part 3 – Shooting shop floor videos

Following are a few recommendations on the art of taking shop floor videos:

This needs to be considered when deciding who will be holding the camera. You will naturally prefer someone who is already handy with it, and that is likely to be from experience capturing family occasions, sports, or from making movies as an amateur. The ability to keep a camera steady and pay attention to lighting, composition and focus is valuable, but the camera operator will have to be coached on the specific objectives of shop floor videos.

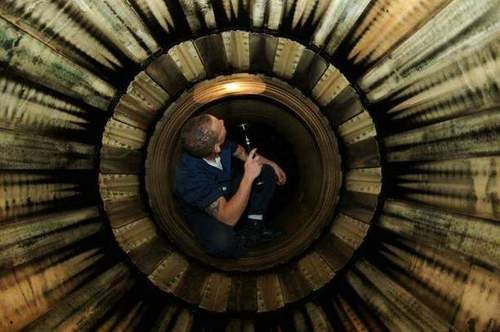

Many plants have mezzanines or catwalks that provide a view from above. Being observed from such a place, however, may be uncomfortable for the operators, as well as too far to zoom in on the hands and capture any voice comments. The middle ground is to shoot from the top of a stepladder located within zooming and hearing range of the operator station, just far enough to avoid any kind of interference

This works, until the operator leaves the station to walk beyond the reach of the zoom, at which point getting down off the stepladder to follow the operator while recording causes a few seconds of the action to be lots. A better solution is to hand over the camera to another team member on the ground, or even to involve more than one camera. In any case, this needs to be planned. Image stability is not an issue on the stepladder, but it is when following an operator’s movement across the floor, and you do not want a video that will make participants sea-sick during review. While professional tracking shots require equipment that is not available in a factory, some amateurs have supplemented the camera’s own image stabilization by shooting from a wheelchair.

All we need for this purpose is one representative execution, and the operator can tell us if there is anything special or abnormal about it. If possible, we just take it into account during the analysis; otherwise, we make another recording. To make sure we have one complete execution, we start recording a few seconds before the operation starts and stop a few seconds after it ends.

Share this:

Like this:

By Michel Baudin • Technology 1 • Tags: Photography, Plant video, Shop floor, SMED, Video, Video analysis, Work Sampling