Oct 11 2012

To journalists: if you write about Lean, check your facts!

An otherwise informative newspaper story about a company’s Lean approach in a local newspaper contains the following paragraph:

“The heart of lean is kaizen, a Japanese term. ‘Kai’ means to take apart, and ‘zen’ a striving toward perfection. Kaizen is a process in which a team of employees is brought together to focus on a problem that needs solving or a process that needs improving. Improvement is continual, and that’s the striving for perfection. Edward Deming, a statistician from the U.S., brought the idea to Japan after WW II when he struggled to get American manufacturers to listen to his ideas. Lean and kaizen principles were widely adopted by Japanese manufacturers and helped Japan rebuild after the war.”

This is a remarkable paragraph. Other than saying that Kaizen is Japanese, every statement in it is inaccurate. Let us review them one by one:

- “The heart of lean is kaizen,..” Well, not really. It’s only part of it. You can’t implement Lean with just Kaizen, and you can practice Kaizen without being Lean.

- “‘Kai’ means to take apart,…” Not in my copy of Nelson’s Japanese dictionary! ‘Kai’ means change, renew, mend, not “take apart.”

- “…and ‘zen’ a striving toward perfection.” In the same dictionary, Zen means good, goodness, right, virtue, not “striving” for anything, let alone “perfection.”

- “Kaizen is a process in which a team of employees is brought together to focus on a problem…” What about Kaizens done by individuals through a suggestion system?

- “Edward Deming, a statistician from the U.S., brought the idea to Japan after WW II…” It’s W. Edwards Deming, and what he brought to Japan was not Kaizen but statistical quality control.

- “Lean and kaizen principles were widely adopted by Japanese manufacturers and helped Japan rebuild after the war.” Assumes Lean and Kaizen existed before Japan’s post-war reconstruction.

The rest of the article is actually interesting, informative, and credible about the specifics of the case. It didn’t need a paragraph of background. If, as a journalist, you write about a case of Lean implementation, don’t write such a paragraph without checking the facts.

Oct 14 2012

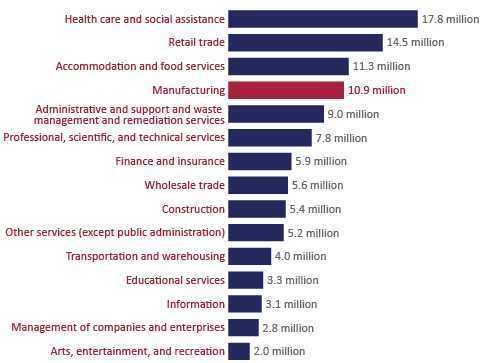

Manufacturing bouncing back as US, Colorado companies reshore jobs – Denver Post

See on Scoop.it – lean manufacturing

This is an “I told you so” moment. For years, we were telling US manufacturers that it made business sense to improve their existing operations, only to hear executives say “We’ll skip Lean and go straight to China.”

In emerging economies, low wages are temporary, and they come with low productivity and quality, long lead times across oceans, and high logistics costs. As the work force learns manufacturing, wages rise along with performance, and the cost advantages vanish.

Admitting there are cases where chasing low wages around the world makes economic sense, in most, if you invest in an emerging economy, you do better by betting on its future, and developing relationships that pay off more and more as it grows, for example by building local factories to serve the local market, as the top car companies have done in China.

See on www.denverpost.com

Share this:

Like this:

By Michel Baudin • Press clippings 0 • Tags: Manufacturing, Reshoring