Jan 14 2014

And around and around it goes | Bill Waddell

See on Scoop.it – lean manufacturing

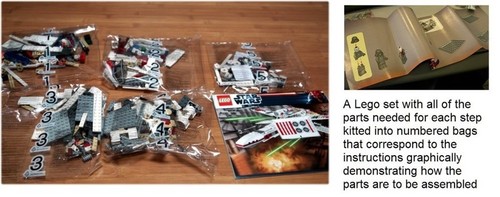

You can do many things with Legos, like our own Leanix™games, and this article shows an example where a team of accountants who were given parts in kits and assembly instructions from Lego performed 40% faster than a team of engineers who were given the parts in single-item bags and only pictures of the finished assemblies.

In drawing far-reaching conclusions from this example, however, Bill is comparing apples and oranges. It was faster to assemble from kits because somebody at Lego had kitted the parts, and the kits were complete and accurate. A fair comparison would require including the time needed for this. Kitting may still win, but not by a 40% landslide.

In a real manufacturing situation, you buy components and materials from specialized suppliers and, if you want kits, you have to put them together before assembly. Whether it is justified or not depends on what you are producing and on the parts you use.

Let us assume you are making custom-configured products on a mixed-flow line, but there is one screw that is used in all configurations. You are better off presenting this screw on the line side in bins than distributing it across kits.

On the other hand, it often makes sense to kit configuration-specific parts off line. It requires less labor overall but, most importantly, the work of kitting is done in parallel with assembly rather than in the final assembly sequence, which can cut in half the start-to-finish assembly time on the line.

Even then, however, you have issues with kitting errors by operators who don’t know the product, kits rendered unusable by a single defective part, and part stealing from kits, which is often done as an immediate remedy to the above.

See on www.idatix.com

Jan 16 2014

What a Coffee Cup Taught Me About Poka Yoke and Human Errors | Peter Abilla

See on Scoop.it – lean manufacturing

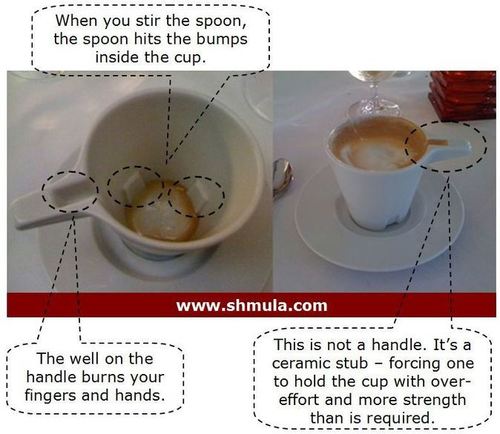

“Human Errors, Poka Yoke are concepts brought to life from my experience with coffee cup. One can learn a lot about Poka Yoke and Human Errors. This is a story about what a coffee cup taught me about how poor design in our products and systems invite human error.

Many years ago, I had to travel to Dublin every few months for work. […] One very early morning while waiting for the taxi to pick me up at my hotel to take us to the airport, my colleague with whom I was traveling with at the time had ordered coffee while I ordered a Coke since I’m not a coffee drinker. They brought him his coffee in this cup.”

With its unsightly bumps and nooks, the “fancy cup” you show is not even pretty, which makes you wonder what the designer had in mind. The issues you bring up, however, are more about usability engineering in Don Norman’s sense, than Poka-Yoke.

A properly designed handle is self-explanatory in that any user who has never seen a cup will immediately understand what it is for. But it doesn’t make the cup mistake-proof: there is nothing physically preventing you from pouring coffee onto it while it is upside down.

Usability engineering is about controls that look and feel distinctive to the touch — as opposed to rows of identical buttons — that give you feedback when you have activated them, that have shapes that naturally lead you to use them properly, that respect cultural constraints in the meaning of shapes and colors, etc.

Applying these principles in designing human interfaces reduces training costs and the risk of errors. It is valuable, but it does not prevent errors.

Incidentally, why do so many cultures, including Japan and China, use cups with no handles? An alternative to handles to avoid burning your fingers is the double-walled cup, and I have seen some from China. Otherwise, I have resorted to the Arab way of holding a handleless tea cup: between my thumb on the bottom and my index finger on the rim.

See on www.shmula.com

Share this:

Like this:

By Michel Baudin • Blog clippings 3 • Tags: Mistake-Proofing, Poka-Yoke, Usability Engineering