Mar 28 2012

More musings on “Muda” (Waste)

Let us return to the slogan “Muri, Muda, Mura,” and see if there is something new to say about Muda, the one that is discussed to death. Just in this blog, it is already the subject of the following four posts:

- “Muda” just means “Unnecessary”

- Management Whack-a-Mole and the Value of Lean

- A factory can always be improved

- Occam’s Razor, Value Added, and Waste

What more is there?

Definitions of waste

In daily life, a “waste of time” is an activity that you can stop doing without any adverse effect. It is no different in manufacturing: an activity is “muda,” (waste) if you can stop doing it without lowering your performance in any way; a device is “muda” if you can dispose of it and nothing gets worse. Stopping overproduction, for example, won’t hurt your quality, productivity, delivery, safety, or morale. It is a simple and actionable idea: if you look closely enough at what you are doing on a manufacturing shop floor, you can tell in those terms what is necessary from what isn’t.

Many authors, however, feel compelled to make it more complex, more abstract, and less actionable. Following are a few examples of attempts to define waste — as a translation of Muda — that I think are generating more heat than light:

- Anything that does not physically change the product. Shipping does not physically change the product. Yet, unless we can manufacture at each customer site from materials extracted from the ground right there, delivery is impossible without shipping. Packaging prevents the physical form of the product from being changed during shipment, which would make it defective. Calling packaging or shipping “waste” when both are obviously necessary to order fulfillment is. at best, confusing.

- Anything that the customer is not willing to pay for. Manufacturing involves many tasks that customers need not be aware of, let alone express a willingness to pay for. You don’t ask customers whether they are willing to pay for revision control on engineering changes. If, however, you stopped doing revision controls, the consequences on quality would be dire. Therefore it is not waste.

- Not doing things right at the first time. This brands as waste any activity that requires experimentation or iteration.

Ohno’s list

Ohno’s list of seven types of waste is the subject of countless PowerPoint presentations, most of which I find not only tedious, but actually misleading. The most common misconception is that the seven list entries are mutually exclusive categories. The point of Ohno’s list is not to categorize the waste but to help you recognize it when you see it. It guides your observations when you walk the shop floor. The items in Ohno’s lists are symptoms rather than categories. You can observe both overproduction and excess inventory, but they are obviously not independent phenomena.

Ohno’s list has seven elements because it is Japanese, and seven is a lucky number in that culture. Other Japanese lists of seven elements include the old 7 tools of QC and the new 7 tools of QC. Akira Kurozawa’s movie is the Seven Samurai, and the samurais’ way of the warrior specifies seven virtues… It may be related to Buddhism having seven factors of enlightenment. Although it also has lists of seven, like the deadly sins or T. E. Lawrence‘s biblical Pillars of Wisdom, the Judeo-Christian world prefers lists of 10, like the 10 commandments or the US bill of rights.

I think this is one cultural reason so many want to expand Ohno’s list. All sorts of additional entries have been proposed, including skills, unused competence, unused space, government, meetings, unemployment, complexity, poor communication,… It is not clear to me that such additional entries belong in parallel with Ohno’s seven or help you identify waste on a manufacturing shop floor. As Rogério Bañolas pointed out, however, Ohno’s list is not necessarily on-target in activities other than manufacturing.

There are also practical considerations about the length of lists. Seven entries is about as many as people can remember. Lists of ten are too long: few Americans can tell you what the 8th amendment to the US constitution says, and only the most devout Jews and Christians can recite all the ten commandments. Lists of 14 even worse, like Woodrow Wilson’s or Deming’s 14 points, to which I would add Jeffrey Liker’s 14 principles of Lean in The Toyota Way.

TIMWOOD and possible misunderstandings

Even a list of seven is a challenge to remember without the help of a mnemonic like TIMWOOD, which stands for “Transportation, Inventory, Motion, Waiting, Overproduction, Overprocessing, and Defects.” It is undeniably useful, but we have to be careful in not being misled by it in at least the following two ways:

- The sequence of items is dictated only by the need to fit the acronym, and has no implication of priority. Just because Transportation is listed first does not mean it is more important or common than Overproduction.

- The words making up TIMWOOD are memory joggers, not definitions. While all Waiting, Overproduction, Overprocessing and Defects is waste, the same cannot be said of Transportation, Inventory, and Motion. As discussed above, delivering products to customers is transportation but not waste. If you literally have zero inventory, you can produce nothing, and some handling of parts is necessary. For these types, as Ohno actually phrased it, the waste is the following:

- Unnecessary transportation. This includes, for example, moving the same bin multiple times between the warehouse and a production line.

- Excess inventory. Common telltale signs that inventory is excessive are that no one knows its purpose or that is has not moved in three years.

- Unnecessary motion. This includes long carries from a shelf to an assembly station, and multiple handling, such as picking a part from a bin, setting it down on the work station and then picking it up again to mount it on the product.

The qualifiers make the explanations a bit more complicated. Without them, however, the list may look more elegant but it does not make sense.

“Just get rid of it!” won’t

Once you have identified waste, all you have to do is get rid of it, right? If only it were that simple! Sometimes it is, but rarely. Most of the time, getting rid of waste involves both technical and managerial changes, and going after each observed item of waste one by one would be ineffective. The list can be very long, and its entries interrelated. That is why you organize Lean implementation in projects to redesign production lines, increase equipment flexibility, or change policies in production control, maintenance, quality, human resources, etc. The waste that is observed is the gold in the mine; the projects, the means of extracting it.

Technically, getting rid of the waste is always feasible, because, by definition, waste is unnecessary. There is, however, a difference between knowing that something is feasible and having done it. That is where Lean implementation skills come into play. Learning of the existence of opportunities is an important first step, but only the first step.

Mar 31 2012

Metrics in Lean – Part 1 – Requirements

Ever since childhood, we all want to know what grades we get on our report cards, and what these grades mean in terms of how well we are doing. We want to be evaluated based on parameters we understand and we can affect by our efforts.

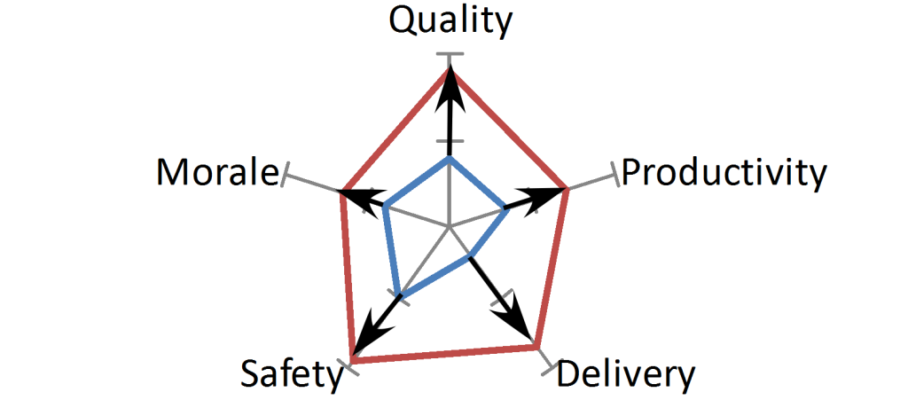

A key issue in manufacturing is consistency as we go from a shop to a department to an entire plant and to the company as a whole. We don’t want to use parameters in terms of which excellent local performance can aggregate to poor global performance. Once performance measures are selected, the next challenge is to use them as a basis for management decisions that are in the best interest of the company while being fair and nonthreatening to employees. In particular, actions taken to improve one aspect of performance must not degrade another. In addition to these issues, in a lean environment, we need to consider the impact of improvement projects, before and after they are carried out.

Share this:

Like this:

By Michel Baudin • Metrics 4 • Tags: KPI, Lean, Management, Metrics