Apr 27 2022

Flow

In his latest post on AllAboutLean, Christoph Roser compares the flow of materials in a factory with the flow of traffic on roads. About flow, he asks “But what is it?” but stops short of giving an answer. I also wrote many posts about flow without ever bothering to answer that question. It seemed so obvious and self-explanatory that it didn’t require defining but, perhaps, it does.

Contents

Literal Flow

Defining such a basic concept is more difficult than it seems. Oxford Languages does a miserable job of it. As a noun, it assigns two meanings to flow :

- The action or fact of moving along in a steady, continuous stream.

- A steady, continuous stream of something.

If flow is a special case of a stream, then what is a stream? Look it up in the same dictionary and find that a stream is a special case of flow. Merriam-Webster is less circular. To them, flow is, among other things, a smooth uninterrupted movement or progress.

Defining Characteristics

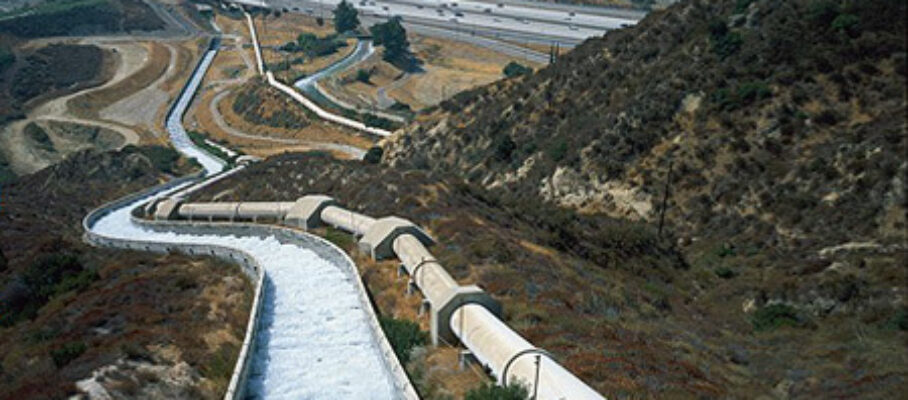

Qualifiers like steady, continuous, smooth, and uninterrupted are key. Carrying a single bucket of water from point A through a gate to point B stops at point B and is therefore not steady. There is no water at point B until a whole bucketful arrives at once, and it is, therefore, neither continuous nor smooth, and it is interrupted by the gate. It is not flow. On the other hand, the movement of water through an aqueduct is steady, continuous, smooth, and uninterrupted. It is a literal flow.

Approximations

Lacking a firehose, early fire departments used a line of firefighters passing buckets to each other to approximate a flow, whence the term “bucket brigade.” It is not related to the bucket brigade system in production.

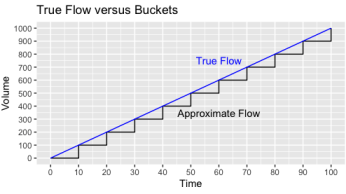

The difference between flow in a pipe or hose and its approximation is seen by plotting the cumulative quantities going through any point along the way:

With the bucket brigade, you have a staircase instead of a smooth line. The smaller the size of the stairs, the more alike the two curves look. Also, as the members of the bucket brigade work in sequence, the flow through the whole line is determined by the slowest members. Let’s see how this simple concept crosses over to other domains than moving fluids.

Flows in Manufacturing

In Manufacturing, we almost never have flow in the literal sense. There is literal flow inside a continuous casting process but the input is molten metal in discrete ladles, and the output is cut into discrete billets. Flow, however, is used figuratively for movements of materials, data, and money when they have similar characteristics to the flows of fluids.

We don’t apply it, for example, to an individual project, because it ends once a goal is reached, and everything about it is temporary. On the other hand, you can see projects as flowing through an engineering office, and jobs through a job-shop. Some service organizations even call their workload a pipeline, in which all projects/cases/jobs go through multiple phases, from initial discussions with clients to completion and delivery.

Materials

If building a bridge is a project, making 1,000 units of a product or product family every day looks more like a flow. If we can organize to do it in a network of operations, each holding discrete units moving at regular intervals, it looks like a flow and we call it a flow, in a figurative sense. It is an approximation, and takt-driven production is the closest this approximation can be.

Recalling that the takt time of a production line is the time that must elapse between consecutive unit completions to meet the demand within the available work time, takt-driven production holds exactly the materials needed for one finished unit of product at each operation during the takt time and passes it on instantly to the next one when it ends. Takt-driven production is itself an ideal that provides a direction for improvement, often called True North. Ohno’s seven types of waste all correspond to departures from takt-driven production, and any change in part of the network that brings it closer to takt-driven production is an improvement for the whole.

Physical flows

You can test whether a production setup deserves the name of a flow line by drawing a spaghetti-map of the movements of materials. If the map is inextricable, as in Lean Leaper’s example from the Lean Post, you can’t call it a flow line:

Spaghetti maps serve mostly to demonstrate how absurdly convoluted the movements of materials are in a shop, and you don’t usually need to draw them exhaustively to make the point. The following picture, translated from Shunji Yagyu, shows the conversion of a short assembly line converted to a chaku-chaku line:

The line of red arrows on the top looks very much like a flow. I didn’t repeat it on the bottom because it is the same path that the operator follows.

Logical Flows

We can observe materials moving between machines in existing lines. If, in the paths of the materials, we forget the machines and their positions, we see the state changes of the materials. For example, a car door exterior goes through a sequence of states:

- Coil

- Rectangular sheet

- Rectangular sheet with holes

- Formed shape

- Plated shape

- Painted shape

This is what you start from when designing a manufacturing process. Then you choose the means by which to effect the state changes and move the materials. We still call it a flow, but, compared with the physical flow, it is one level of abstraction higher.

Flow-Shops in Scheduling

The term “flow-shop” has a specific meaning in the theory of scheduling. In a general job-shop, you have jobs to process through machines but the different jobs may visit the machines in different sequences and not all jobs go through all machines. Scheduling a general job-shop in a way that is optimal in some sense is an inextricable problem that is fodder for papers in Operations Research. A flow-shop is a simpler, special case in which all the jobs visit all the machines in the same sequence.

In Manufacturing, most production lines are flow-shops in this sense; tool rooms that sharpen tools, refurbish dies or build jigs and fixtures are closer to general job-shops. Because a flow-shop uses machines in the same sequence, it makes sense to lay them out in sequence so that the output of each flows directly into the next one. In a general job-shop on the other hand, there is no sequence, and you usually lay them out in “farms” of identical machines. In practice, however, you often encounter flow-shops laid out like job-shops, with convoluted spaghetti maps.

Data

Water in an aqueduct moves by gravity but manufacturing workpieces require prompting. Human hands, handling devices, conveyors, forklifts, trucks, trains, etc., move them. These movements happen based on instructions issued by some system, and the system transactions record their starts and completions. It means that the flows of materials are associated with movements of data that are referred to as data or information flows, in directions that are commonly the opposite of materials flows.

As I wrote about in an earlier post, there is a fundamental difference between movements of materials and data. Once you retrieve materials from a warehouse, they are no longer there, and you need to update the inventory; on the other hand, no matter how many times you read the same data from a database, it is still there.

You never step in the same river twice because the water you stepped in before has gone. You feel the same because the same amount of new water replaced it. Likewise, you never step into the same warehouse twice. It looks the same because Materials Management replenished it with parts identical to the ones you saw the last time.

Data is the stuff that’s read or written, two operations that are different from withdrawing and inserting materials in warehouse operations. Data propagates rather than flows.

Information

Information flow and data flow are often used interchangeably, in Value Stream Maps and other places. You even use the same unit, the bit, to quantify information and data. When you receive a 1MB picture in an email, it’s 1MB of data. Depending on what you learn from it, it is at most 1MB of information. If it allows you to tell which one of 2 equally likely objects it shows, it gives you 1 bit of information; if it’s which one out of 128 equally likely objects, it’s 7 bits of information. When you receive the same picture a 2nd time, it’s still 1MB of data. The redundant data, however, give you no information.

This makes information yet another kind of flow, more abstract than data and more remote from the literal flow of water in an aqueduct, and one in which the quantity received depends on the condition of the receiver.

Money

Sales, wages, materials, energy, outsourced services, and investments all involve transfers of money over time. These are often called “cash flows.”

“Cash flow” evokes bills flowing down like water and buying a house with a suitcase full of bills. None of these, however, has anything to do with what the money people mean by cash flow.

To them, any sum of payments made or received by a business entity is a “cash flow.” It does not imply a method of payment. Contrary to all the flows discussed above, it’s not a rate. It’s dimensionally different. You size an aqueduct in terms of cubic feet/second; a production line, in units per hour; a communication channel, in MB/sec… A cash flow, on the other hand, is just a sum of money. It’s not per unit of time. You use it in expressions like “Company X had a cash flow of $21B since 2015.” To be consistent with other uses, it would have to be, for example, “Company X had a cash flow of $3B/year since 2015.” In other words, “flow” in other contexts is the derivative of what it means in Accounting.

If they want investment projects approved, engineers need to know how to justify them economically. Most large corporations use Discounted Cash Flow analysis. It entails generating a schedule of outflows and inflows triggered by the project over time. You then summarize this schedule into metrics like Breakeven Time and Internal Rate of Return that management mandates thresholds on.

Flow in Psychology

Psychologist Mihaly Csikszentmihalyi appropriated “flow” to designate “a state of concentration or complete absorption with the activity at hand and the situation.” The closest you can come to relating this, even metaphorically, to water in an aqueduct is to envision the activity as “flowing” through the mind of the person, but it’s far-fetched.

Psychologist Mihaly Csikszentmihalyi appropriated “flow” to designate “a state of concentration or complete absorption with the activity at hand and the situation.” The closest you can come to relating this, even metaphorically, to water in an aqueduct is to envision the activity as “flowing” through the mind of the person, but it’s far-fetched.

Conclusions

People use the word “flow” for many different things. In every discussion, we need to set the context in order to communicate about it.

#flowline, #jobshop, #materialflow, #dataflow, #informationflow, #flow

April 27, 2022 @ 1:44 pm

How do you improve any of these flows ex. manufacturing flows?

April 28, 2022 @ 1:42 am

Hi Michel, a few years back I also tried to develop a more formal and also measurable indicator of “flow”. When joining Valeo, as part of policy deployment, I was in need of translating the overall strategy into something for my function which was true to the strategy, but also simple and compelling to communicate to the plants. In the end, the two words that captured the essence of what we were trying to do were: “create flow”.

But how to actually measure where we were? How to set targets? And how to check progress? Otherwise, “flow” remains at the level of a concept and a source of heated debates.

In a series of three posts, I developed these measures for the “flow of work” going from “flow rate” (in the first post: https://thejitcompany.com/perfect-flow-1/) to measuring “flow velocity” (in the second post: https://thejitcompany.com/perfect-flow-2/) and finally “flow smoothness” (in the third post: https://thejitcompany.com/perfect-flow-3/).

Look forward to your feedback.

(Note: also posted on LI).

April 28, 2022 @ 7:08 am

To complement Rob’s super 3-piece, interested readers could learn a variety of strategies to Design For Flow: Minimize Flow, Maximize Uni-directional Flow and Minimize the Cost of Flow in this presentation https://www.leanandflexible.com/wp-content/uploads/2016/11/PFA_Essential_Foundation_for_JobshopLean.pdf . I think that there should be a conversation on HOW to achieve Flow i.e. layout, product design, product mix rationalization, scheduling, material handling with supplier-customer situational awareness, etc.

April 23, 2024 @ 2:14 pm

The future of your company will not ultimately be determined by the flow of the value streams you create within your organisation; but by the ‘Experience Streams’ you create for your customers to enjoy in the marketplace. This will then create one of the most important flows, the flow of orders into your company. The effect of all your internal values streams is to create the experience streams that will satisfy & exceed all your customer’s physical & emotional needs & wants more effectively than your competitors. The goal is to combine all these streams to create a torrent of competitive advantage. The most important and neglected internal value stream is created by releasing, focusing & developing the combined abilities* of all your people. Without this stream flowing all the other flows cannot achieve their most effective flow rate. The brightest leaders understand their main task is to enable their people to shine; & their abilities to flow. With this combined brightness, brilliant organisation are created

*Human ability has three dimensions.

Skill – the ability to learn & perform existing tasks effectively, efficiently & enjoyably.

Creativity – the ability to continuously improve what we do & the way we do it.

Enthusiasm – the emotional ability/energy to enjoy developing & applying the first two.