Nov 11 2011

From scancards to “personal kanbans” and Ybry charts

Professionals know that their productivity drops when they take on too many concurrent projects. An engineer whose attention is split across 15 projects doesn’t contribute effectively to any. But it happens because supervisors keep piling on assignments without regard to this phenomenon. Over the years, cures have been proposed under different names, all aiming to cap work in process.

About 1982, a colleague showed me the system he used to manage what he was working on. It was called the Scancard System, and it used the hardware in Figure 1. The cards were square, with 3 1/4-in sides and borders of different colors. They came with letter-size card pocket plastic boards that you could insert into 3-ring binders, keep on your desk or pin to a wall.

He used it with one column for his backlog of things to do, one column for work in process, and one column for completed items. It was a paper-based system but, at the time, so was almost everything we did. It gave you visibility, it capped the number of items you were working on at one time, and moving cards from one column to the next was an effective metaphor for the flow of your work. The ads showed smartly dressed managers using their scancard systems in meetings. I went for it and used it for years, until I had a project with a company that used another system and switched to fit in.

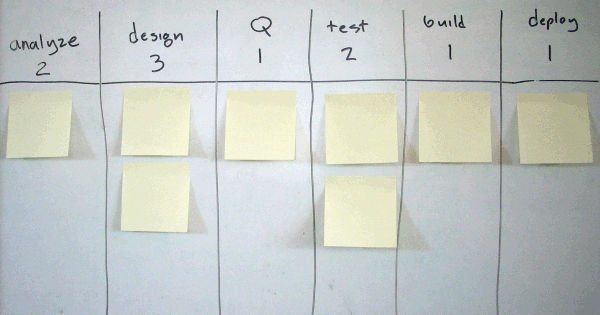

Fast forward to 2011. Scancard Systems is out of business, and I hear of a system called “Personal Kanban,” that is focused on providing visibility and limiting work in process, using a white board and Post-Its as in Figure 2:

I put quotes around the name because I find it to be little more than a feat of vocabulary engineering, leveraging the buzz around a feature of Toyota’s production control system to repackage ideas that have little to do with it, are very simple and have been around for a long time. A software developer visiting a factory may see a similarity with Toyota’s Kanbans, but it escapes me.

Of course, if, as in Figure 2, it is on a white board, you can’t carry it with you to a meeting or share it in your network. The Personal Kanban website advertizes an iPhone app called iKan, that I can’t find on Apple’s App Store. On the other hand, Leankit Kanban offers a web-based application with an iPhone version that looks very much like a team to-do list management system. It looks most useful if your work can be perceived as a collection of independent activities, which happens if each Post-It is for a whole project or for a prospect in a sales cycle. But it would not fit if each Post-It were for a task within a project, with precedence constraints or iterations between tasks.

Another limitation of such a status board is that is only shows current status, as compared, for example, with the Ybry chart of Figure 3, which shows the complete history of each project by using a line for each project rather than a card. Like the status board, it assumes that all project go through the same sequence of phases.

Figure 3. Ybry chart for projects going through the same sequence of phases

Ybry charts were invented by Charles Ybry in 1846 for railroad scheduling, and are still used for that purpose. See Edward Tufte’s Envisioning Information, pp. 107-110. The work-combination charts used in Lean operator job design are a variation on this method, as explained in Working with Machines, pp. 133-154.

November 14, 2011 @ 2:25 am

Hi Michel,

For a second I read scancards as “scandals”.

In any case, it was a good read. It’s nice to see that kanban is really gaining some steam…

The personal kanban: not just “vocabulary engineering.” |

November 16, 2011 @ 4:18 am

[…] by Dan Michel Baudin, who most assuredly has forgotten more about lean than I’ll ever know, wrote recently about the “personal kanban” and concluded that it was much ado about nothing on three counts. […]

November 17, 2011 @ 10:00 am

Sadly, this is such a typical industrial engineer’s reaction to use of kanban systems in knowledge work and personal productivity – focused on practices and failing to recognized shared principles.

Would it surprise you to learn that kanban systems were not, in fact, invented by Toyota, and in fact pre-date industrial manufacturing by several hundred years? Kanban (meaning single (usually wooden) tokens), used to represent and limit quantities of scarce resources, used in sets and circulated in systems have been in use for hundreds of years in Japan. Taiichi Ohno observed just-in-time restocking of shelves in American grocery stores and realized that he could use kanban to signal the restocking. The Toyota kanban systems evolved from that initial insight and the recognition that controlling inventory inside the factory and providing predictable lead times, was desirable.

If you start from the same principles that control WIP and providing predictable lead time is valuable for personal or knowledge work where do you go from there? Invent something entirely new or take inspiration from hundreds of years of existing knowledge and results?

When you apply principles to a new domain, new specific practices evolve. These may not look like practices from another domain – this doesn’t make it wrong, or a “feat of vocabulary engineering.” It shows a depth of insight and a recognition of underlying principles.

November 17, 2011 @ 12:19 pm

Spoken like a typical… What? I don’t think in those terms. You are an individual. I would not presume to reduce you to just a member of a group, whatever that group may be. If you can use the Kanban label to market the idea of putting a cap on the number of projects a group works on, that’s wonderful for you.

For me, the loose usage of the term Kanban — in manufacturing and other fields — impairs communication. Likewise, if you consider coins and credit cards to be the same thing because it’s all money, you make it difficult to discuss the specifics of each.

In contemporary everyday Japanese, a Kanban is a shingle that you hang outside a store, literally a “board you see.” If wooden tokens have been used in Japan for hundreds of years, I would appreciate it if you could tell me by whom, when, for what purpose and in what form.

I have heard the story of Taiichi Ohno visiting a supermarket in the US as the origin of the Kanban system. Given that supermarkets don’t use Kanbans, I find the story not quite believable. It sounds like the output of a PR department. I have heard another: when Toyota was nearly bankrupt in 1950, it couldn’t pay for full trucks of parts. Allegedly, Kiichiro Toyoda came up with the idea of reordering exactly the quantity of parts that was on cars actually sold, which the company could afford. The circulating cards then became a convenient way of counting that quantity and placing orders. It may not be true either, but it makes more sense to me.

Best regards.

January 2, 2012 @ 12:17 pm

Comment in the Lean Six Sigma discussion group on LinkedIn:

January 2, 2012 @ 12:19 pm

There is more to kanbans in manufacturing than limiting WIP. For example, kanbans tell operators exactly what they should be working on and in what sequence. No judgement call required. Move kanbans also replace routing slips, by specifying items, quantities, origins and destinations.

January 2, 2012 @ 12:20 pm

Comment in the Lean Six Sigma discussion group on LinkedIn:

January 2, 2012 @ 12:22 pm

Comment in the Lean Six Sigma discussion group on LinkedIn:

From Ybry charts for railroad scheduling and project management to work-combination charts | Michel Baudin's Blog

March 3, 2013 @ 6:40 am

[…] to let regular trains through in the opposite direction. In an earlier post, I discussed the charts invented by Charles Ybry in 1846 for railroad scheduling, and this newscast shows that they are […]

January 14, 2024 @ 5:46 pm

The original ScanCard Systems in the pictures and screenshots do not seem to track the phase of projects or specifically instruct people to limit WIP in a certain column. The website of ScanCard Systems on WayBack machine essentially describes it as a portable visual tickler file used to help people to pay a little attention to a large number of projects at once.

However if one wanted to I think they could make a decent Personal Kanban system using The ScanCard System. Also I think that Personal Kanban boards bear almost no resemblance to Kanban as it was used in factories to limit overproduction and overstocking.

However it must be pointed out that knowledge work, and office work, is more unpredictable, and cannot be managed using the exact same implementation that factories manufacturing physical projects use.

However the general idea of Kanban is to visualize work, limit WIP, decrease lead times, and ensure continuous flow. Personal Kanban and team kanban boards do precisely that. They are designed to pull work Just in Time.

Their implementation and the objective of ensuring flow, was likely inspired by lean principles used in factories, but not developed at all by the Ohno, or anyone in Toyota, and not part of the Toyota Production System(TPS).

So I guess I agree with your article that the development team Kanban boards, and personal kanban boards were not developed by or associated with Toyota or TPS, but their implementation and overall focus on flow and lead times was likely inspired by the Lean ideas used in factories, but for a completely different work environment.