Apr 25 2013

Achieving one-piece flow | Darren Dolcemascolo

See on Scoop.it – lean manufacturing

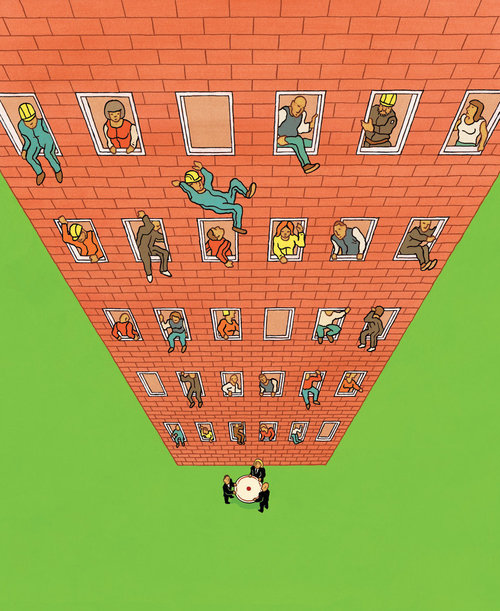

“Sometimes referred to as “single-piece flow” or “continuous flow,” one-piece flow is a key concept within the Toyota Production System. Achieving one-piece flow helps manufacturers achieve true just-in-time manufacturing. That is, the right parts can be made available when they are needed in the quantity they are needed. In the simplest of terms, one-piece flow means that parts are moved through operations from step to step with no work-in-process (WIP) in between either one piece at a time or a small batch at a time. This system works best in combination with a cellular layout in which all necessary equipment is located within a cell in the sequence in which it is used.”

In the current issue of Reliable Plant, Darren Dolcemascolo explains the concept and the value of one-piece flow in simple terms, including the prerequisites for it to work.

See on www.reliableplant.com

May 1 2013

How do I analyze historical consumption for 13,000 items?

Supply chain consultant Hadas Gur asked the following question:

You do not give a context. Are those SKUs components supplied to a manufacturing company or retail items on supermarket shelves? The demand patterns may be radically different. In retail, for example, the demand for milk is the sum of the quantities bought by a large number of individual consumers acting independently, and the normal distribution is a likely fit. On the other hand, if you are supplying a model-specific part to a car manufacturer, it is unlikely to fit.

Do not try to apply the same approach to all 13,000 SKUs! For example, reorder point makes no senses for the 6,000 items that have had no demand in the past 5 years. You would want to investigate whether they should still be in the catalog and, if so, they are strangers and you need to organize to make or buy them when an order arrives.

For the others, I would suggest you explore the data rather than focus on fitting a distribution, starting with a Runner/Repeater/Stranger analysis. Then, starting with runners, investigate trends and seasonal variations. For repeaters, I would investigate ways to group them into families that make sense for what you are trying to do.

Do not use only the data. In order to understand what is possible, you need to visit the warehouses or distribution centers and understand how physical distribution distribution is organized, and the people involved.

Then consider a range of approaches for different items and item families, including just-in-sequence, Kanban, two-bin, reorder point, vendor-managed inventory, consignment, etc. Examine how these approaches would have performed with the consumption pattern of the last 5 years. You can also simulate future demand.

Share this:

Like this:

By Michel Baudin • Answers to reader questions 0 • Tags: Kanban, Manufacturing, Normal distribution, Reorder point, Retail Trade, Stock-keeping unit