Oct 15 2012

Lean in a press shop

Andrew Turner, Managing Director at Ramsay Engineering, in Pietermaritzburg, South Africa posted the following question on The Lean Edge on 9/22/2012:

“Our company is split in 2 sections, the one a JIT assembly plant, the other a mass production Press Shop. Implementation of Lean in the JIT plant has been relatively simple (not that Lean is ever really simple), however, we are struggling with the implementation in our Press Shop. I know the importance of items like SMED and Heijunka in driving this journey, yet we are battling to get the ball rolling forward. Where do you think we should start the process in the Press Shop?”

To date, he has received responses from the following authors:

- Art Byrne: First link the logical value streams through product families, then get change over times under 10 mins

- Mike Rother: Depends on Your Goals

- Peter Handlinger: Establish a daily pattern production schedule to sequence your presses

- Tracey Richardson: Start with Production Control and Empower People through Standards

Of these, Art Byrne’s is the most specific and actionable. None of them, however, address the issue of skills development. At the outset, neither the press operators nor their managers can be expected to have a working knowledge of Lean or how to implement it. Therefore, feasibility by the organization you have is key in your initial choice of projects.

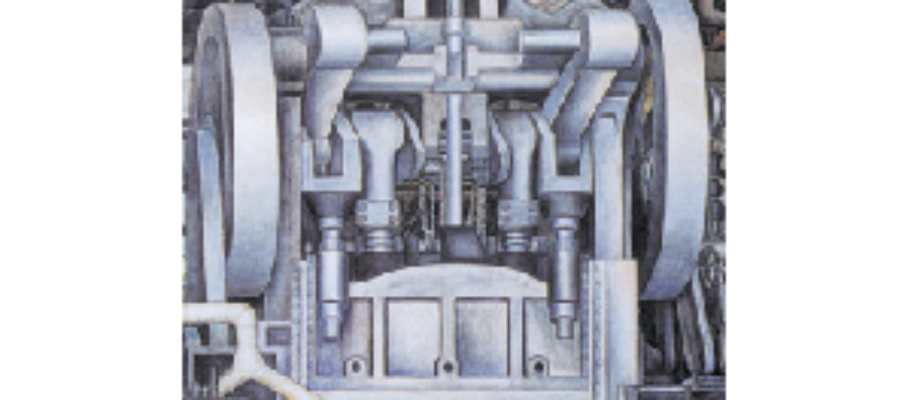

This is why, in shops where people work with machines, the first pilot projects are so often about SMED. This includes not only press shops but machine shops, injection molding shops and diecasting shops, with different technical specifics. On press operations, see Chapter 7 of Sekine & Arai’s Kaizen for Quick Changeover. Keeping in mind the skills development goal, you don’t start with your largest machine that currently takes 8 hours to set up, but with a small one that takes 30 minutes and that you can take down to 4 minutes in 2 months. This kind of success fires up your teams to take on tougher challenges.

After a successful pilot, when you want to apply SMED as appropriate in the entire shop, you need to analyze your activity to establish where it is most useful and easily achievable, and you need to realize the engineering implications. You usually cannot achieve SMED on presses with organization and standard work only; you also need to modify the machines, standardize the dies, and improve the flow of dies to and from the machines, including die maintenance, storage and retrieval. You have to know what and how long it takes to do it. This is not the sort of goals you reach with a few Kaizen events.

Peter Handlinger is the only responder to mention the issues of high- versus low-volume items, but only in the context of setting up daily schedules. I prefer to refer to this as demand analysis, and do it upfront, far upstream from production scheduling, with the objective of breaking down the output of your press shop into the following:

- Runners, to each of which you dedicate on or more press or press lines.

- Repeaters, that you group in families by feature similarity to make in flexible press lines.

- Strangers, that are items with low and sporadic demand that you make in small job-shop inside your press shop.

You use this breakdown to drive changes in the layout of your shop. In particular, it tells you which presses or press lines you can integrate with an assembly line, as Art Byrne recommends. Then you apply different approaches to production control for the different types of lines.

Oct 19 2012

Hospital uses ‘lean’ manufacturing techniques to speed stroke care | Science Codex

See on Scoop.it – lean manufacturing

See on www.sciencecodex.com

Share this:

Like this:

By Michel Baudin • Press clippings 0 • Tags: Health care, Lean, Lean manufacturing