Oct 12 2018

For Lean Production to Work, a Company Needs to Be All In | Ellen Rosen | The New York Times

“For a company in Chesterfield, Mo., it involved something as seemingly simple as attaching a trash can to an employee’s chair. For one in St. Louis, it meant leaving the cover off an electronic temperature controller. For others it’s meant gathering employees from the chief executive on down for what’s known as Kaizen events — based on the Japanese word for continuing improvement. What do these seemingly unconnected efforts have in common? They are approaches to what is known as lean manufacturing — or, more recently, lean production — aimed at streamlining production processes, enhancing employee engagement and increasing profits.”

Source: The New York Times(10/11/2018)

Michel Baudin‘s comments: Thanks to Kevin Hop for drawing my attention to this article. Like him, I do read The New York Times regularly and usually appreciate the quality of its reporting. This article, however, does not measure up. It reflects the conventional wisdom on Lean manufacturing which, if anything, explains why so many implementations fail.

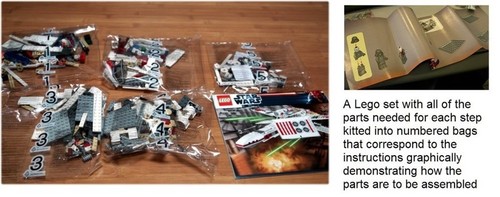

“Not long ago I conducted an exercise with a client in which two teams of three people assembled a Lego product. One team of three folks from accounting was given the 500 or so pieces the way Lego presents them – kitted in bags of parts that align with the largely graphic instructions. Basically, all of the parts needed to make sub-assembly

“Not long ago I conducted an exercise with a client in which two teams of three people assembled a Lego product. One team of three folks from accounting was given the 500 or so pieces the way Lego presents them – kitted in bags of parts that align with the largely graphic instructions. Basically, all of the parts needed to make sub-assembly

Dec 27 2019

Get Rid of Your Print Handbooks!

Among the dusty tomes Dan Markovitz accused me of hoarding in my office, I found eleven handbooks. They occupy two linear feet of shelf space, and I have a few more in electronic form. The print books have indeed been accumulating dust because they are no longer where I look for information.

For theories, the first stop is Wikipedia; for details on using a software tool, StackOverflow; for changing headlight bulbs in my car, YouTube… The last time I opened a handbook was to check a claim that it covered a particular topic. It didn’t.

Contents

Share this:

Like this:

By Michel Baudin • Uncategorized 3 • Tags: Engineering Handbook, industrial engineering, Quality Handbook