Nov 29 2011

More about Kanbans, and What it Takes to Use Them.

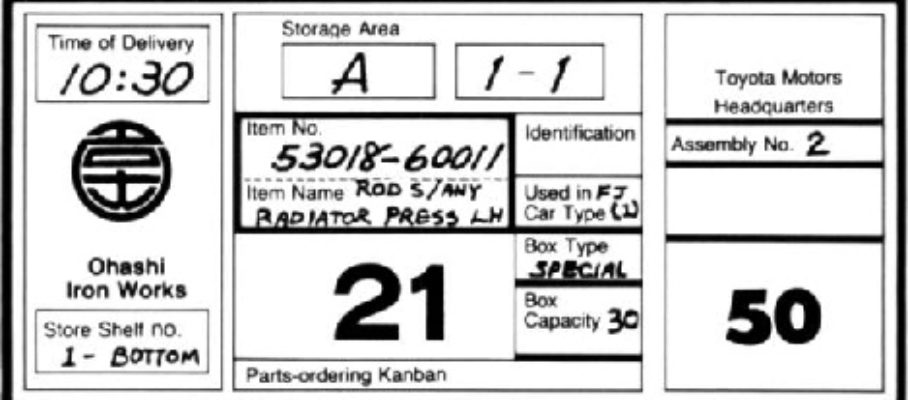

Ever since the world outside of Toyota started noticing its production system in the late 1970s, the Kanban system has received a disproportionate amount of attention compared to other features. It does not mean, however, that it has been accurately implemented in many of the factories that claim to have done it. To anyone who cared to study it, details have been available in English at least since Robert Hall’s Zero Inventories (1983), the JMA’s Kanban, Just-In-Time at Toyota (1985), Yasuhiro Monden’s Toyota Production System (1993), or an updated treatment in Lean Logistics (2005).

Pressured to implement Kanbans by executives to whom it was little more than a buzzword, many manufacturing professionals found it more expedient to take old, familiar approaches like the two-bin system or reorder-point and call them Kanban. One such system implementing reorder-point through cards placed on a board has become so popular in France that I suggested calling it “French Kanban.” As can be seen in Figure 1, each column on the board is a mirror of the inventory level for an item. Each pocket filled by a card corresponds to an empty slot in stores, so that the remaining amount is visually indicated by the empty pockets on top. The reorder point is crossed when the cards reach the red zone.

Figure 1. French Kanban: Reorder-Point with Cards

Figure 1. French Kanban: Reorder-Point with Cards

Meanwhile, a few academics like J.T. Black at Auburn University or Robert Hall at Indiana University took the trouble to thoroughly investigate the Toyota system as a whole and the Kanban system in particular, but most of their colleagues didn’t, preferring a simplistic rendition of the Kanban system that made their own ideas stand out by contrast. In this context, insisting on the genuine Kanban system is perceived as nitpicking, because the differences are not in the big idea but in the details. You can easily dismiss these details as insignificant until you consider their cumulative effect on thousands of shop floor transactions every day.

Here are two examples, found today in a blog post:

- A common misconception is that you pull a Kanban from a bin when it is empty. If this were true, you would just be using a card to implement the Two-Bin system. The Kanban is not pulled when the bin is empty but when you withdraw the first part from the bin, to allow the bin to cover consumption during the replenishment lead time.

- Another in the same post was that the eKanban system did not involve physical cards. It is conceivable that, in the future, goods in transit will only be identified by RFID tags, but it is not the state of the art. They still need some form of human-readable identification and routing, for which a purely electronic system would require some kind of screen on each container. In fact, the electronic signal is used only in the return part of the loop, to eliminate the labor-intensive, slow and error-prone handling of unattached cards. On the supplier side, you print single-use cards that are attached to bins for transfer to the customer. When you detach the car on the customer side, you scan its barcode, and this triggers the electronic replenishment signal.

When evaluating or learning a tool like the Kanban system, you have to consider the following:

- The objects. They may be cards carrying specific data, bins of particular sizes and configurations, electronic messages of a given structure, … This is what we have to play with. Their physical nature makes a difference, not in a philosophical way but in basic, practical ways. For example, cards can be shuffled and posted on boards but bins cannot. When you send a card, you no longer have it, but when you send an electronic message, you still do. With the former, you have to make sure it doesn’t lose its way; with the latter, that it isn’t accidentally sent multiple times.

- The rules. These are protocols for users to follow. They specify who is allowed or required to do what to which objects when. In the Kanban system, the rules say who can issue new Kanbans or remove them from circulation, who attaches Kanbans to bins and detaches them, and what events trigger these actions. The rules give the objects meaning, as the rules of poker do to a deck of cards.

- The mapping to reality. This is what happens to materials and goods in production and logistics when people follow the rules. When applied rigorously in the right context, the Kanban system tells production operators and materials handlers exactly what they should work on. Unlike the traditional dispatch lists, instructions in the form of Kanbans leave no ambiguity and require no judgement call by the leader or supervisor.

Within its range of applicability, the Kanban system is both simple enough for people to apply and sophisticated enough to get the job done. This is a tall order, and we should not underestimate what it takes.

Even in Japanese, the word Kanban has many different meanings, the most common being a sign advertising a store on the street, as you can see by searching Google images for “看板” (Kanban). Figure 2 shows, on a sidewalk, the Kanban of a beauty salon located on the 2nd floor of the building.

Nov 29 2011

Aravind: an example of Lean health care in India?

Via Scoop.it – lean manufacturing

Heard on NPR this afternoon. Lean was not mentioned, but, if Aravind has found ways to perform cataract operations faster, better, and cheaper, it probably deserves to be called a Lean organization.

Via www.npr.org

Share this:

Like this:

By Michel Baudin • Press clippings 0 • Tags: Health care, Management