May 6 2020

The Math of COVID-19, And Factories

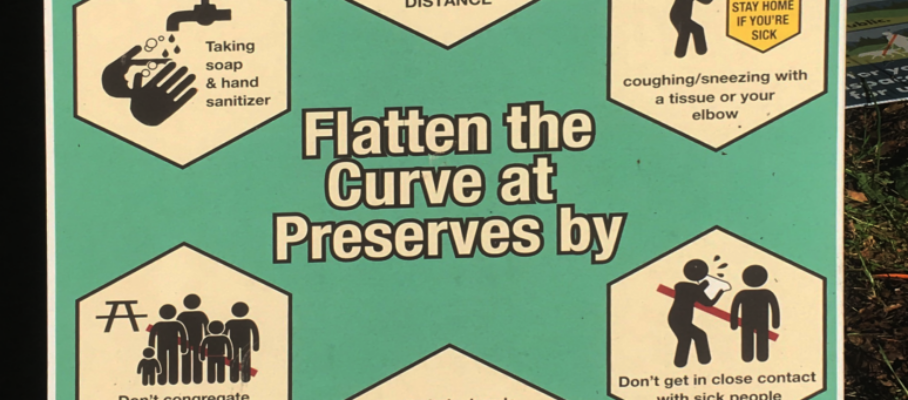

Whether we like it or not, the past months have given us a crash course in epidemiology. COVID-19 has taken terms like reproduction number, herd immunity, social distancing, or flattening the curve from research literature to daily news and instructions for visitors to California State Parks.

We are in the middle of a pandemic we have partially tamed by putting the economy in a coma. This pandemic has already killed more Americans in two months than the Vietnam war in 20 years and we are facing the unprecedented challenge of restarting factories in this context.

Among the many things to learn in a hurry, are what epidemiologist Adam Kucharski calls the rules of contagion, as they apply to the people who work in a factory and its surrounding community.

Quality control is the closest most of us in Manufacturing ever get to serious statistics/data science. It’s not the same domain as epidemiology, and there is little crossover in tools or methods. This is to share what I have just learned about this topic. I welcome any comment that might correct misconceptions on my part or otherwise enlighten us.

May 8 2020

A Lifetime Of Systems Thinking | Russell Ackoff | Systems Thinker | June-July, 1999

While this article is from 21 years ago and about systems thinking, Ovidiu Contras felt compelled to share it on LinkedIn today, because of the following quote:

“My fourth source of fun has been the disclosure of intellectual con men—for example, propagators of TQM, benchmarking, downsizing, process reengineering, and scenario planning. Managers are incurably susceptible to panacea peddlers. They are rooted in the belief that there are simple, if not simple-minded, solutions to even the most complex of problems. And they do not learn from bad experiences. Managers fail to diagnose the failures of the fads they adopt; they do not understand them…. Those at the top feel obliged to pretend to omniscience, and therefore refuse to learn anything new even if the cost of doing so is success.”

Source: Systems Thinker, June-July, 1999

Michel Baudin‘s comments:

“Lean” is not in the list of panaceas. Before finding solace in this omission, however, we need to consider the vintage of the article. It’s from 1999, when flip phones were cool. Writing today, the author might have included Lean, Six Sigma, Lean Six Sigma, TOC, Agile, and, on the other hand, omitted dead horses that have long been buried.

While the “belief that there are simple, if not simple-minded, solutions to even the most complex of problems” is certainly mistaken, the approaches peddled as panaceas sometimes contain nuggets of wisdom applicable to specific problems. The mistake is to go global cosmic and promote them outside their range of applicability. My own comparative analysis is from 2013, and would also need an update to include the more recent panaceas.

Reading the whole of Ackoff’s article, I had no issue with most of his points but a few stood out, about which I had a few comments. Russell Ackoff, unfortunately, died in 2009 and won’t be able to reply.

Share this:

Like this:

By Michel Baudin • Press clippings 2 • Tags: Systems thinking