Aug 14 2012

Metrics in Lean – Alternatives to Rank-and-Yank in Evaluating People

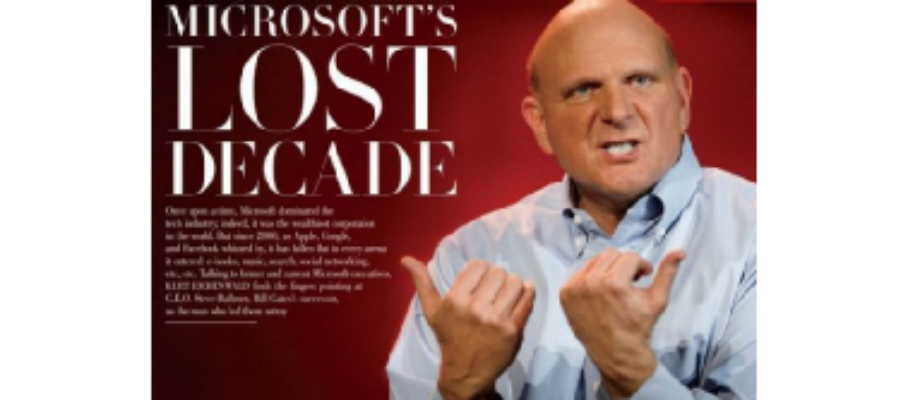

The July, 2012 edition of Vanity Fair had a cover story about Microsoft and the damage caused to the company by its stack ranking system, also known as rank-and-yank. This story caused a flurry of responses in the press, including an article in Forbes defending the practice. The idea is not just that employees should be evaluated individually and ranked, but that the bottom few performers should be mercilessly culled from the work force, thus bringing up the overall level, tightening the performance range, and motivating survivors for the next round. This assumes that the performance of employees can meaningfully be reduced to a single number, and that living in permanent fear of losing your livelihood is the best motivation for improvement.

According to another Forbes article, GE, the company that championed Rank-and-Yank in the 1980s, abandoned it in 2005. Another once celebrated showcase of this method is the notorious Enron, and now Microsoft is under fire because of it. Yet, according to the same article, the practice is now widespread among large American corporations, hidden under a variety of names. But where is the evidence that it actually works in the long term?

Aug 17 2012

Decisions about Making Decisions |IndustryWeek

See on Scoop.it – lean manufacturing

Good points. On the issue of delegation, I apply the “sleep-at-night” test. You can delegate the authority to make a decision, but not the responsibility. Can you sleep at night knowing that you will be accountable for a decision that you let another person make? If you can’t, stay in the loop. Once you trust the person, get out of the way.

See on www.industryweek.com

Share this:

Like this:

By Michel Baudin • Press clippings 2 • Tags: Lean, Management