See on Scoop.it – lean manufacturing

“If companies can identify their high movers from a pick history list, the “vital” 20% can be optimally located within the shelving systems to maximize production efficiencies and to minimize wasted time and effort. The 80/20 Rule can help companies strategically locate “vital” materials so that employees’ efficiency and safety are maximized.”

“If companies can identify their high movers from a pick history list, the “vital” 20% can be optimally located within the shelving systems to maximize production efficiencies and to minimize wasted time and effort. The 80/20 Rule can help companies strategically locate “vital” materials so that employees’ efficiency and safety are maximized.”

Michel Baudin‘s insight:

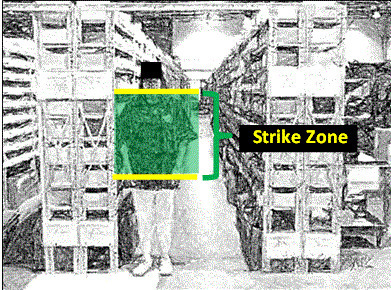

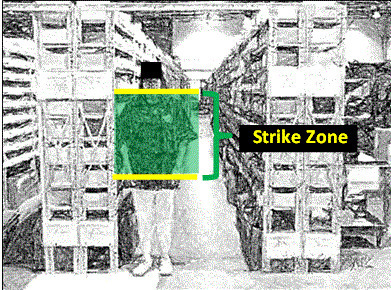

In this article ergonomist Lance Perry explains that organize items in warehouses by frequency of use improves the ergonomics of manual storage and retrieval.

In Lean Logisitics, I presented the same policies as a means of increasing productivity and reducing the lead times of warehouse operations. Making what you use the most often easiest to reach improves multiple dimensions of performance at the same time. There is no tradeoff; you don’t rob Peter to pay Paul; you don’t make X better by making Y worse. That’s why we call is an improvement.

What is most puzzling is that such a simple idea is not already universally applied.

See on www.industryweek.com

Like this:

Like Loading...

Related

Aug 23 2013

How the 80/20 Rule will improve the safety of your warehouse | IndustryWeek

See on Scoop.it – lean manufacturing

“If companies can identify their high movers from a pick history list, the “vital” 20% can be optimally located within the shelving systems to maximize production efficiencies and to minimize wasted time and effort. The 80/20 Rule can help companies strategically locate “vital” materials so that employees’ efficiency and safety are maximized.”

“If companies can identify their high movers from a pick history list, the “vital” 20% can be optimally located within the shelving systems to maximize production efficiencies and to minimize wasted time and effort. The 80/20 Rule can help companies strategically locate “vital” materials so that employees’ efficiency and safety are maximized.”

In this article ergonomist Lance Perry explains that organize items in warehouses by frequency of use improves the ergonomics of manual storage and retrieval.

In Lean Logisitics, I presented the same policies as a means of increasing productivity and reducing the lead times of warehouse operations. Making what you use the most often easiest to reach improves multiple dimensions of performance at the same time. There is no tradeoff; you don’t rob Peter to pay Paul; you don’t make X better by making Y worse. That’s why we call is an improvement.

What is most puzzling is that such a simple idea is not already universally applied.

See on www.industryweek.com

Contents

Share this:

Like this:

Related

By Michel Baudin • Press clippings 0 • Tags: Ergonomics, Lean, Lean Logistics, Materials Handling