Dec 15 2020

Nissan’s Quick Response Quality Control (QRQC)

Nissan’s Quick Response Quality Control (QRQC) is a management approach. It’s about organizing the response to quality problems, not about the technical tools used to solve them. It is intended to help detect problems, solve them, and document solutions, thereby growing the skills of the workforce. QRQC neither mandates nor excludes mistake-proofing or any statistical/data science tool.

This is meant to introduce QRQC to those who have not heard of it but it is also a call for practitioners to correct any misperceptions, add details, or share their experience.

Contents

Lean, TPS, and QRQC

QRQC is covered neither in Juran’s Quality Control Handbook nor in John Bicheno’s Lean Toolbox, nor in any publication from the Lean Enterprise Institute. It is not part of the Toyota Production System. It actually originated at Nissan and spread to France’s automotive and aerospace industries. In Japanese, the Nissan Production Way (NPW) (日産生産方式, 2005) lists it among its “25 keywords” and devotes four pages to it. In French, Radu Demetrescoux’s Lean toolbox (La Boîte à Outils du Lean) has a two-page spread on it. Perfect QRQC, Vol. 1 and 2, by H. Audia et al. are the only books dedicated to QRQC on Amazon.

Origin and Diffusion

Kazuo Kawashima is generally credited with inventing QRQC. Originally a design engineer at Nissan, he transferred to production at the Nissan Kyushu plant in 1993 and was put in charge of transmission and assembly quality for four Nissan plants in Mexico.

At the Kyushu plant, Kawashima had observed that the solution of quality problems was delayed by the lack of peer-to-peer collaboration at the level in the organization that was closest to the Point Of Occurrence (POO). The organization was in silos and, for example, to obtain engineering resources for a shop floor problem, a team leader’s request wound its way up and down the hierarchy before it could be approved.

Not only did this process lose time, but it filtered and mangled the information beyond recognition by the time he could act on it. His goal with QRQC was to have teams with all the requisite skills acting autonomously, as close to the POO as possible.

Adoption at Valeo

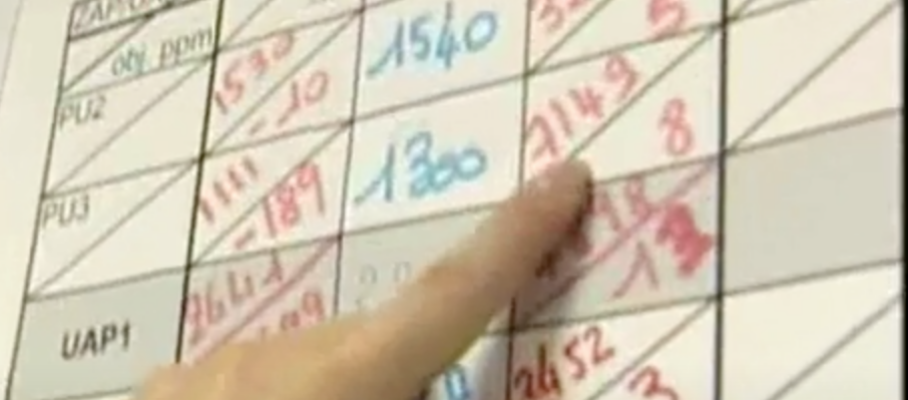

In 2001, Carlos Ghosn brought Kawashima back to Japan to select the best suppliers. One of the suppliers he evaluated as French auto parts maker Valeo, which hired him to implement QRQC in 2002. Valeo publicized its approach in this 2017 video from their Angers plant:

Adoption at Faurecia

Kawashima’s success at Valeo caught the attention of other French auto parts makers. In 2006, Faurecia recruited Kiichiro (Ken) Sato, the Sr. VP in charge of Supplier Quality for the Renault-Nissan Alliance to implement QRQC. Faurecia now calls it QRCI, for “Quick Response Continuous Improvement,” which suggests a broader scope than just quality. In 2010, Faurecia posted the following video on its QRQC implementation at its Henin-Beaumont plant:

Adoption in Aerospace

Kawashima and Sato had different perspectives on QRQC and its implementation, Both, however, were successful at Valeo and Faurecia respectively, which raised interest in the approach in other industries, and aerospace in particular with Groupe Safran.

QRQC, however, has not been as successful in aerospace as in automotive, for reasons that are open to speculation. A concept like takt time from the German aircraft industry transferred successfully to automotive in Japan, and therefore cross-pollination between these industries in possible.

What is QRQC?

As explained in NPW, QRQC focuses on quick response to anomalies and defects occurring on the production shop floor. It is a generic term for a system that now targets both quality and other problems. QRQC includes both action in real-time on the production line and longer PDCA cycles on a shift or daily basis, involving engineers and managers.

In real-time QRQC, each production operator detects anomalies and malfunctions as they occur on each workpiece. This is a mechanism to respond on the spot, in addition to the quality checkpoints. It is also a structure to prevent defectives from escaping downstream.

Daily or shift QRQC is for the management system to promote fundamental problem-solving based on data for the anomalies and malfunctions uncovered by real-time QRQC.

The Goals of QRQC

The goals of QRQC are similar to those of Toyota’s JKK:

- To prevent defectives from moving down the production line. Do not make defectives and, if you do, do not pass it on! Deal with it on the spot.

- To make problems visible and solve them quickly. In principle, problems revealed by real-time QRQC are analyzed and countermeasures taken by the next day. Problems that technically require analysis are solved in a week.

- To make each operator quality conscious and make the entire production sensitive and responsive to quality issues.

Range of Applicability

NPW describes QRQC as applicable to any production line with a sequence of operations. The relevance of a day or a shift, however, depends on the volume of activity that takes place within these periods. If not immediately stopped, a station in a car assembly line with a takt time of 60 seconds. that starts malfunctioning can make hundreds of cars defective within one shift. An aircraft assembly line with a takt time of 3 days is a different matter, so is a computer assembly plant with a takt time of 3 seconds.

QRQC Structure

QRQC aims to address each problem by the people closest to it, at the lowest possible level in the management hierarchy. This requires a structure and an escalation process, from the production line, to the team or shop level, and to the whole plant level.

Key Points of Implementation

Per NPW, the first point is to make sure that operators actually stop the line when they see an abnormality. This assumes giving the operators criteria to identify abnormalities and defects and the means of reporting them on the spot. The operator presses a line stop button or pulls a stop rope. Traditionally communication has been through andon lights and boards, and location-specific music. Today, you can issue alarms through wearable devices like smartphones or smartwatches.

Support departments — Engineering, Production Control, Quality Assurance, and Maintenance — assist by promptly collecting and analyzing data on the POO, identifying the root causes of abnormalities and defects, and taking immediate countermeasures, visualizing and sharing information as needed for this purpose.

The following infographic, translated from NPW gives an idea of QRQC in operation:

Daily QRQC Procedures

Assuming that the plant practices real-time QRQC, each production operator or quality checker worker immediately informs the supervisor of any abnormality or defect and takes countermeasures on the spot. When taking countermeasures is too difficult, they make sure the next operation is notified of the need for corrective action. If this is not in place, too many items pop up at final inspection to analyze and identify trends daily. Once it is, the activity daily QRQC proceeds as follows:

- Data Entry and Information Sharing. Final inspection captures the abnormalities and defects that escaped the production process and the quality checks and enters them into the information system in real-time for communication to all departments.

- Preparation of QRQC Meeting. Participants in the QRQC meeting decide what to report at the meeting based on slicing and dicing the data, analyzing and identifying trends from all operations, and final inspection.

- The QRQC Meeting. Supervisors and members of the support departments meet for 30 to 40 minutes every morning to (1) share news — including items other than quality — (2) assign responsibility for countermeasures, (3) track the progress of countermeasures, and (4) confirm their effectiveness. They confirm results for yesterday’s problems and issue instructions for today’s. They document the decisions in forms like the “Quality Improvement Know-how Sheet” or the “Status Report Sheet” for sharing.

- Analysis and implementation of countermeasures. Following the directions of the QRQC meeting, the representatives from each department analyze the defects and devise countermeasures. For abnormalities and defects caused by product or process design rather than the production line, a lead time of a week is allowed to define the countermeasures.

- Ensuring durable countermeasures. You incorporate them into the work instructions and update other master data as needed.

Tools and Techniques

The red box focuses attention on defectives: you fit all stations where you check quality with a red box or bin for defectives. It is simple but, obviously, not applicable to any product that doesn’t fit in a bin. Consequently, you can’t use it for cars or airplanes. In addition, it constrains color-coding because you can’t use red containers for any other purpose.

The QRQC literature also references PDCA and the “Three Actuals” (San Gen Shugi, 三現主義). PDCA is a broad outline of problem-solving. The “Thee Actuals” is an alternate formulation of Toyota’s Genchi-Genbutsu. It means: go where it happens, focus on reality, and deal with actual objects. This is as opposed to discussing slides in a conference room. Note, however, that the NPW infographic includes two conference-room scenes.

The problem descriptions answer the classic 5W1H questions — Who, What, Where, When, Why, How — with the addition of How many. The system relies on forms to ensure that the teams answer all questions. The 5W1H questions are what journalists learn to answer in the lead of every news story. How many, on the other hand, is manufacturing-specific.

Immediate Countermeasures

The description does not distinguish between immediate countermeasures like additional inspections or tests that prevent defectives from escaping and solutions that eliminate the root cause of the problem. If you cannot solve the problem instantly, you use immediate countermeasures to keep operating while searching for the root cause. The NPW infographic suggests that they do, in practice make this distinction.

Ford’s 8D problem-solving approach does make this distinction, and it is explicitly referenced in QRQC implementations outside of Nissan. The “D” in 8D stands for “discipline” rather than “step,” which suggests that they are not strictly sequential, and there are 9 rather than 8:

- Preparation and Emergency Response Actions

- Set up a team of people with product/process knowledge.

- Describe the Problem

- Develop Interim Containment Plan

- Determine and Verify Root Causes and Escape Points

- Verify Permanent Corrections (PCs) for Problem that will resolve the problem for the customer

- Define and Implement Corrective Actions

- Prevent Recurrence / System Problems

- Congratulate the Main Contributors to your Team

QRQC participants document the activity on forms and post them on communication boards at all management levels involved. QRQC involves data collection and analysis but does not mandate the use of any particular tools for this purpose.

#qrqc, #nissan, #valeo, #faurecia, #lean, #tps, #npw, #tps, #leanquality, #quality, #qualityassurance

December 15, 2020 @ 8:56 am

I always understood the ‘D’ in 8D to stand for ‘Disciplines’. That’s what someone from Ford told me about 30 years ago, anyway! Things get twisted with time. At about the same time, a GM ‘kaizen hit squad’ (not sure if that had been over-dubbed ‘lean’ by then) had the objective of halving the lengths of conveyors.

When I challenged them on this and dug down, it turned out that in the past some ‘guru’ (or sensei?) had implored them to get rid of conveyors …and chop them in two to avoid them being sneaked back in when the hit squad had moved on!

December 15, 2020 @ 9:55 am

Thanks for pointing out my error about the “D” in 8D. I corrected the post accordingly.

Great story about GM! It sounds like something out of Ben Hamper’s Rivethead.

December 15, 2020 @ 10:51 pm

Comment on LinkedIn:

December 15, 2020 @ 10:51 pm

Comment on LinkedIn:

December 15, 2020 @ 10:51 pm

Comment on LinkedIn:

December 15, 2020 @ 8:04 pm

I remember I saw a big workbook by the assembly lines in Valeo’s Shenzhen plant about 5 years ago. People had to hand-write the problems (1 row = 1 problem detected) by hand. The header on each page read “QRQC”.

The columns followed roughly the 8D steps, with some checkboxes that could be ticked etc. The headers of the table were bilingual (English & Chinese).

They make to short takt time orders. High quantity, with high automation.

December 15, 2020 @ 10:51 pm

Comment on LinkedIn:

February 16, 2021 @ 10:20 am

Hello Michel, I’d first like to start off by saying this problem solving technique is quite impressive, and it seems the necessary infrastructure and people are needed for the system to thrive. Any business looking to install a sense of Lean culture within their organization should definitely consider this quality control method. Also, this is the first time I have been introduced to “Ford’s 8D problem solving approach,” and it has proven to be a useful technique for Ford overtime.