Apr 26 2013

Lean implementers: don’t forget engineering!

Just about everybody says that the involvement and personal engagement of top management is the main challenge in Lean implementation. “Key to the success of lean manufacturing,” said the keynote speaker at an industry association meeting in Santa Clara, CA, “is that the leadership team needs to fully buy into the method and remove workplace obstacles so that employees can achieve results.” While he didn’t say it, I am sure his audience heard that management doing as he says is all it takes to implement Lean successfully.

In an informal survey taken recently by blogger Vivek Naik among his readers, no one mentioned insufficient mastery of the engineering and management tools of Lean as a cause of failure. The existence of tools is generally recognized, but most consultants and implementers take them for granted. They are assumed to be simple, widely known and not new. Some, like Bill Kluck, even call the tools “trick shots.”

When you read that the details of Lean tools are widely known, you wonder where and by whom. How many manufacturing managers or engineers do you know who understand heijunka, cell design, work-combination charts, SMED, the proper use of andons, mistake-proofing, or jidoka? Considering that these tools are the results of 75 years of development at Toyota, and that most of the Japanese literature on Lean is about technical content, I find this dismissal cavalier, to say the least.

It does not happen in other human endeavors, like building a world class soccer team. Top management commitment is obviously required, but no one would claim that it is sufficient. You don’t hear of dribbling, passing, shooting, receiving or throw-ins as low-level skills that everybody has anyway and that you don’t need to focus on. Soccer teams actually train relentlessly to develop and maintain these skills, and everybody involved, even the fans, fully realize their importance and admire the star players for their mastery.

To understand the issues, and remedy this situation, I would like to dive deeper into the following topics:

- The engineering dimension of Lean, and the other dimensions

- What is special about engineering on a factory floor?

- Engineers in Lean implementation

- Correcting the imbalance in the US Lean movement

Contents

The engineering dimension of Lean, and the other dimensions

So why is it different in the competitive game of manufacturing? For one, it is more complex than soccer, and few people have a holistic view of it. One who does is my colleague Crispin Vincenti-Brown, and he has identified four dimensions to this game, and you must pay attention to all if you want to win. They are as follows:

- The engineering of production lines.

- Logistics and production control.

- Organization and people.

- Metrics and accountability.

In the US, the Lean movement has ignored the engineering dimension. Logistics receives some attention, but Lean programs are overwhelmingly focused on the last two: organization and people issues, and metrics. It is out of balance, and I believe this is a key reason for Lean programs to fail.

Lean implementers, whether employees or consultants, come from a variety of backgrounds. In the US, few are engineers. You see MBAs, psychologists, marketing people, and the occasional cognitive sociologist and defrocked priest. There is nothing wrong with having all these different perspectives, as long as they don’t blind you to the whole picture. The psychologist takes engineering for granted while the engineer does the same for people issues and the production control manager thinks that everything revolves around planning and scheduling….

On the one hand, you cannot have a successful implementation unless you address all these dimensions in the right sequence. On the other hand, you cannot expect any individual to master all of them, but you need a team that does, in which every member understands that his or her perspective is not the whole picture, and leadership that can pull all the strings into a coherent approach.

What is special about engineering on a factory floor?

This still does not explain why it is Engineering of production lines that is given short shrift, even in a country like the US, that has contributed so much to this field, and that still has a vibrant engineering community in other technical specialties. What is it about the engineering of production that sets it apart?

The heat of the forge, the sparks from welding, or the din of the assembly line, and interactions with the people who work in these environments,… are not for everybody. Most universities do not know how to teach this kind of engineering. Its subject matter straddles what they call Industrial Engineering and Manufacturing Engineering.

Industrial Engineering (IE), as taught in American universities, is generically about how people work, and gives you no process-specific knowledge. Manufacturing Engineering (ME), on the other hand, is heavily focused on metal working operations, as if these were the only processes worthy of the name “manufacturing.” In principle, you should be able to become a Manufacturing Engineer specialized in all sorts of other fabrication or assembly processes, but the label is in fact used only in metal working.

We could expect, however, those who pursue degrees in IE or ME to be comfortable on a production shop floor, but most aren’t. Some years ago, my colleague Hormoz Mogarei and I gave a seminar to PhD candidates in Industrial Engineering at Stanford University. We wanted to tell them what we did to get them interested in working with us. Their response, however, was that it was beneath them, and that they had not gone this far in school to do such low-level work.

For factory work, Shigeo Shingo had identified two types of engineers to avoid: the catalog engineer, whose solution to every problem is buying new equipment, and the “no” engineer, who always has a reason why it can’t be done, has been tried before, or won’t work. One more category that did not exist in Shingo’s day but does today is the PowerPoint engineer, whose focus is animating slides.

Historically, with the exception of Lillian Gilbreth who had a PhD, the key innovators in this field, from Frederick Taylor, Frank Gilbreth and Alexei Gastev to Taiichi Ohno and Shigeo Shingo were all self-taught and had no advanced degrees. To this day, the engineers who are most comfortable and effective on a production shop floor started working there as operators in their youth and later went back to school or learned through continuing education or apprenticeship programs that alternate extended internships with classroom training. These engineers combine the requisite technical knowledge with an understanding of the operator experience and the ability to work with operators on improvements.

Engineers in Lean implementation

And having practical, shop-floor minded engineers in your plant is still not sufficient. You also need to use them effectively. In manufacturing, if you provide an “engineering sandbox,” organize for people to tinker in it, and provide some form of recognition, you will get results. The engineering sandbox is a space set aside and outfitted with the resources needed for tinkering, experimentation, and prototyping. It is used both by individuals and teams.

In Wikipedia, the space you can use to draft an article or an edit before publishing it is called your “sandbox,” and it is similar in concept to the engineering sandboxes you find in factories, that are often called “Kaizen areas” even though the experimentation that takes place can exceed the scope of what is commonly designated as Kaizen. This space is best located in a secluded area, away from heavy traffic and prying eyes and, as it is shared by multiple individuals and teams, access to it must be managed accordingly and often takes place outside of regular working hours. Chihiro Nakao calls this activity “moonshine.”

The implementation of Lean involves engineering projects at multiple scales, from continuous improvement to new plant design. Which no engineering group can be large enough to execute on its own. While many companies set up a “Lean Engineering” group and task it with transforming the entire plant, it cannot work. The engineering group does not have the bandwidth to do no matter how hard its members apply themselves and, even if they did, the production organization would not own their output and would reject it.

The only way it can practically be done is by the production organization, under the leadership of its management at the appropriate level, with the engineers in a supporting role. The concepts emanate from the production organization. The engineers help with calculations, research available resources, generate technical drawings, and coordinate the use of contractors if needed. And they apply the lessons learned through improvement to new plant and new line designs where they play a central role.

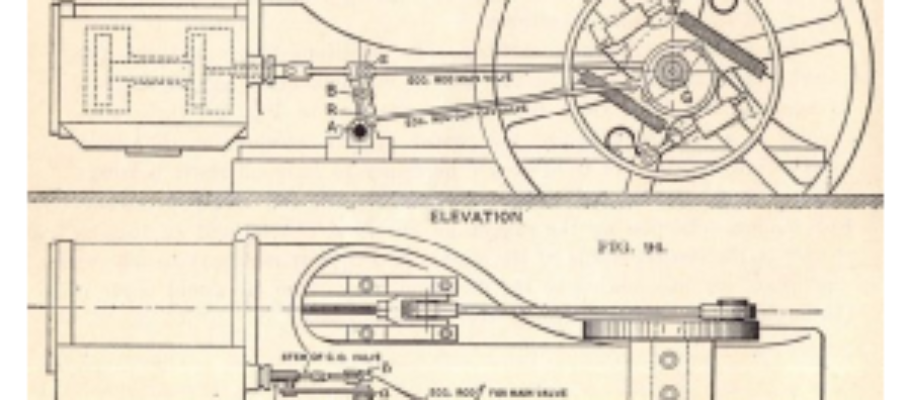

At the start of setup time reduction projects, the focus is on organizing to prepare better before stopping the machine, which achieves initial results, mostly through the work of production operators. But to reduce setup times from 1 hour to less than 10 minutes, you need to go further and modify the machine, which requires engineering. And it’s not all about hardware. More and more machines are computer-controlled, and also require changes to their process programs. The picture to the left shows a device conceived and built by plant engineers, and retrofitted to an injection molding machine to separate the parts by cavity and better trace quality problems.

Correcting the imbalance in the US Lean movement

I am not the only one who has been working to lack of attention to engineering in the US Lean movement. J.T. Black, a professor of IE at Auburn University in Alabama, now in his seventies, was possibly the first American academic to recognize the significance of Lean and make it central to his teachings. Art Smalley, a consultant who is a Toyota alumnus, has also been vocal. But it is an uphill battle. Two of my books, Lean Assembly and Working with Machines, are on this subject, and both are outsold by Lean Logistics, which isn’t.

April 26, 2013 @ 3:26 pm

Thanks Michel, another great post and reminder that the core skill of engineering remain so important.

April 26, 2013 @ 5:09 pm

I would like to add some additional evidence to your article. Years ago, when I would hire an engineer, I would have them spend a minimum of a month working on the shop floor and/or field service as part of the introduction. Several mentioned to me later that they had considered quitting during that time. However, in the same breath they would mention how enlightening the experience was. Not only in learning the application of their work but the relationships they built. Once they moved into the office it was not unusual for them to be found on the floor asking questions.

Heck, I did not even know about at Lean at that time, Just seemed like the way you should do it.

April 26, 2013 @ 7:55 pm

Michel, this post is another example of what I appreciate about your contributions to our community’s understanding of lean manufacturing. You constantly remind us that the fundamentals of manufacturing and lean are deceptively challenging and not commonly understood. And in doing so there is no scolding, one-ups-man ship or academic arrogance.

And then there is the writing. Your clean and measured prose enables the logic of ideas to flow forward so smoothly that it makes detailed analysis of interdependent phenomena appear effortless…like a goal-scoring bicycle kick by Pele. (I’m showing my age here). That you bring the history of science and ideas to bear in your reflections is an unexpected bonus.

Finally, your postings encourage closer examination of dubious notions presented elsewhere as self-evident. And in the best of those gently moderated exchanges it does become clear that – just as in lean – “it’s the easy things that are hard, and the hard things that are easy.” For all this, Michel, thank you.

This “respect for people stuff” | Michel Baudin's Blog

May 8, 2013 @ 1:57 pm

[…] without much attention for the strong industrial engineering roots it also has.” While I agree with Rob, I am not sure this is what Seddon […]