Nov 8 2011

Factory life with and without Kaizen

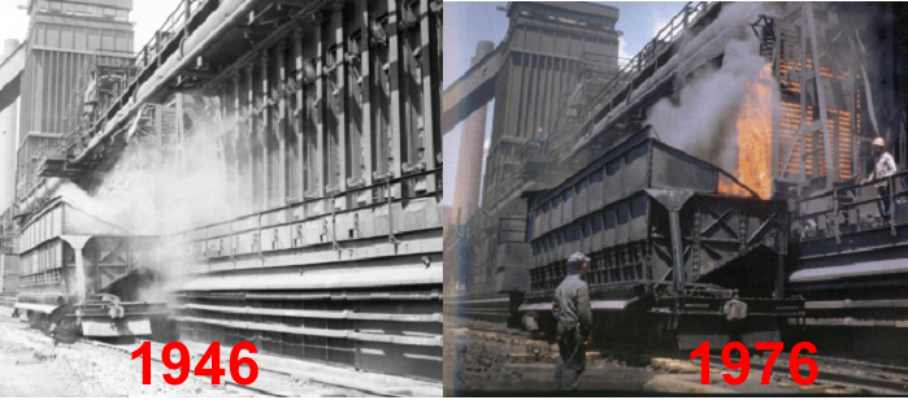

In Kaizen, Masaaki Imai describes Japanese executives returning in the 1970s to American plants they had visited thirty years before and being struck by the absence of change: they saw the same production lines with the same equipment operated the same way. This started me looking for photographic evidence. Overall, pickings were slim, but I did find the above pictures of the same coke oven at the Ford River Rouge plant shot in 1946 and 1976.

If there is Kaizen activity in a factory, how does it change the work life of employees at all levels? The following chart compares the breakdowns of their use of time, with and without Kaizen:

In a plant without Kaizen, operators and supervisors are fully occupied with routine daily tasks: production for the operators, expediting parts, enforcing discipline, and record keeping for supervisors. Only middle managers and executives spend a fraction of their time on projects involving capacity changes, new production lines or new technology. Nobody works on incremental improvements to the way the work is done today.

By contrast, Kaizen involves employees at all levels in such improvement activities to different degrees. Between improvement and daily routine, the boundary is sharp; between improvement and innovation, fuzzy. Over time, the cumulative effect of incremental improvement is radical change by itself. In addition, the skills acquired and the lessons learned from incremental improvements are incorporated into new line or plant design projects. In some Japanese auto parts plants, I remember seeing automatic lines side-by-side, where one used old machines that had been gradually retrofitted with devices that reduced the need for human intervention, while the other one had been built from scratch with new machines to be automatic. The Kaizen work done to implement the former was essential to the success of the latter.

November 8, 2011 @ 2:16 pm

Nice article, Michel. Thanks!

Kaizen is like the “Pull” system. It cannot be imposed on people and/or included in their daily schedule by force. And incidentally, that is the DIFFICULT part, making it part of the company culture so it will Pull people towards improvements…

I suggest people, who are interested in Kaizen culture to join us at http://leanwebinars.eventbrite.com/ next week, where we will share many of the inside information.

November 10, 2011 @ 3:49 am

Excellent remarks!

And a very useful representation of the concepts.

November 10, 2011 @ 11:52 am

I also see a contrast in that Kaizen involves a culture of change, which implies certain mindset: changes are welcome, “knowldege between the ears” is dynamic and “external shamans” help steer improvement.

November 15, 2011 @ 11:24 pm

I’d like to start my part of the conversation with this caveat: I’m not arguing with your statements but I would like to put a spin on them if I may be so bold.

My first spin is: Innovators ask, “Where is the best place to solve this problem?” In the instance of the coke oven, the best place to solve problems over thirty years may have been in the use of temperature distribution, how to load the space, providing better internal oven configurations, etc. The last place it would have been effective to solve problems would have been the outside of the oven. Therefore, the returning Japanese executives might have been struck by the absence of obvious / visible change, but the change might have been dramatic nonetheless.

My second quick point is that it is dangerous to assume that the best place to make improvement is always on capital equipment. Maybe the strongest ROI could be gotten out of supply chain efficiencies, etc. Once again, that would not have been visible.

At its foundation, innovation has to do with the effective use of resources. That means the best evidence of innovation might be to find a way to use old capitol equipment (e.g., by learning how to alter internal temperature profiles in real time and on demand) with the least amount of money/labor spent to effect the greatest improvement – something the 30 year old pictures would not demonstrate.

The fourth point I’d like to make is that it may also be a mistake to assume that continuous, small improvements performed today (and everyday) by many people is the best path to real innovation and improvement. Although I’d be foolish to say that Kaizen was not useful, I think I can safely state that Kaizen-inspired improvement might not always be as important as a one-time really big breakthrough by a single person / small team. Invoking a paradigm shift, or overcoming psychological momentum, can bring about quick advantage which can reverberate through the whole product line and/or system for decades.

Finally, the main benefit of Kaizen over inventive leaps-and-bounds may be the affects of continuous change on culture and easing change management.

January 2, 2012 @ 7:57 am

Aarón Montaño, in the Lean manufacturing & Kaizen discussion group on LinkedIn, commented as follows:

January 2, 2012 @ 7:59 am

Simon J Sibarani, in the Lean manufacturing & Kaizen discussion group on LinkedIn, commented as follows:

January 2, 2012 @ 8:02 am

Gökhan Çelikliay, in the Lean manufacturing & Kaizen discussion group on LinkedIn, commented as follows:

My response:

I don’t think that the new products you list qualify as Kaizen, because they represent revolutionary change. E-books, for example, are putting large bookstore chains like Borders in the US out of business. Facebook has been essential in the overthrow of governments in the Middle East. This is way beyond the scope of Kaizen.

In the US, the word Kaizen is often associated with “Kaizen events” that are in fact projects culminating in one week of intense activity by a team and often result in radical changes in one small area of a plant. but Kaizen events are an American invention, in which the use of the word Kaizen does not match the Japanese original.

In Japan, Kaizen designates small changes in work methods conceived and executed by the people who do this work. It is typically organized through suggestions systems or small-group activity. Other structures are used to drive change on a larger scale, called “Kaikaku.”

Kaizen in Japan versus the English-Speaking World | Michel Baudin's Blog

November 30, 2013 @ 3:36 pm

[…] Factory life with and without Kaizen […]

December 4, 2013 @ 6:03 am

Dear sir,

I am Sameer Bhingarde and work in the food industry, I like this article. I would like to learn some kaizen from you related to the biscuit industry. Please send me any article.

Regards

December 4, 2013 @ 7:39 am

I don’t have an example from the biscuit industry. Some readers, however, may, and I am posting your comment to give them a chance to respond.