Aug 11 2019

Smart Floors

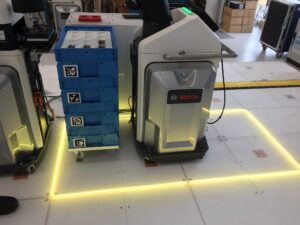

The first stop in Christoph Roser‘s tour of Industry 4.0 in Germany last month was a research facility called ARENA2036, attached to the University of Stuttgart. There, the first demonstration we saw was of the Bosch smart floor, and the pictures included here were taken by fellow participants Franck Vermet and Hironori Hibino.

Contents

ARENA2036

In ARENA2036, ARENA stands for – “Active Research Environment for the Next Generation of Automobiles,” and it is a Public-Private Partnership funded by the German government and hosted by the University of Stuttgart. The “2036” is intended to mark the 150th anniversary of the invention of the car. The relevance of the technology displayed in ARENA2036, however, is not limited to car making.

The smart floor is literally a floor

When Bosch says “smart floor,” they mean it literally. It’s the floor you walk on, not the metaphorical shop floor, with people, machines, materials, methods… The idea of the smart floor is to place devices under it to interact wirelessly with the devices above it.

Purpose of the smart floor

In the Bosch marketing literature, the smart floor caters to a “new compulsion towards hyper-customization […], driven by consumer demand.” I am not sure where the consumers with this compulsion are. I see custom products as a maintenance nightmare. Our toothbrushes, phones, cars, and laptops are all standard versions of popular models, and the only thing custom in my household is the art on the walls.

Getting rid of cables

This being said, there is value of getting rid of all cables on the shop floor, in high-volume/low-mix as well as custom production. Cables cause the following problems:

- As they proliferate, they make keeping track of connection points a challenge. Even when you put multiple devices on a network, it is still cheaper to connect several individual devices to a network interface box rather than have each one equipped with a transceiver.

- If embedded in the floor, cables increase the time and expenses of changing the layout of production lines.

- If they are on the floor, they are trip hazards. They snag people’s legs and get tangled in cart wheels. With screwed-on connectors, a snagged cable can make an electronic box fall off a bench. Connectors that are not securely fastened, on the other hand, come loose even without being snagged, from vibrations. In fact, disconnected cables are the number one failure cause for electronics.

- If cables hang from above, they don’t impede the movements of materials and people and are easy to reconfigure but they may interfere with uses of overhead space, for example by cranes. Devices that hold parts from below and rise as needed are preferrable to cranes because they provide better orientation control and are safer but cranes are still used. Following is an example of power supply to sewing machines from above:

What about other supplies?

A smart floor solves these problems but, unfortunately, production often requires other supplies besides electrical power and data, including a variety of gases, liquids, slurries, or powders, in addition to waste disposal. Using pipes or belts for supply and drainage is even more constraining on layout choices than cables.

The alternative is to deliver these materials to machines in tanks or bags and evacuate the waste in bins. Either way poses its own challenges, which the smart floor does not address.

If done at fixed stations, wireless power supply does not require the floor either. The floor, however, can provide power to a moving AGV along a path.

Beyond the wireless shop

Replacing cables with wireless connections through the floor is only the first step. If you don’t take advantage of what you can do with this technology that was inconceivable with wires your production line will be like an 1886 Benz — that is, a horseless carriage rather than a car. But what are these opportunities? With new technology, they often become visible only from observing the horseless carriage version in operation. At this point, all we can see is the demonstration version.

Wireless data exchange also does not need to involve the floor but, if it does, the floor can contribute to visual management by lighting up parts of itself in response to the activity, as shown in the Bosch demo:

The screen in the back is wall-size for demonstration demonstration but could be on a tablet in actual use. It is the digital twin of the operations taking place on the smart floor. Floor lighting tells to the operator where to locate the cart from the simulation.

The lighting can also be used to help the operator position a work station during setup, as shown in the following pictures:

Maintaining a smart floor

To update or replace any hardware placed under the floor, you need to open it up. The demonstration area in ARENA2036 is not crowded, and clearing a part of the floor for access is not a problem. In an actual, factory, crowded with equipment, it’s not clear how this would work.

The smart floor at ARENA2036

The smart floor is a grid of plexiglass panels separated by strips of LEDs that light up in different colors. In the show room, it is a platform a few inches above the concrete floor of ARENA2036, raised just enough to fit the electronics under it.

Wireless data exchange

For communications, it’s a 5G network, not Wi-Fi. 2G, 3G, 4G, and 4G LTE were successive generations of the networks for mobile phones; since 1999, the wireless local networks connecting devices to internet routers in homes, offices, and factories have been using Wi-Fi instead. 5G is in its early stages of deployment but applies to mobile phones but may displace Wi-Fi for IoT and IIoT as well.

In the US, Samsung is working with AT&T on manufacturing applications og 5G in Austin, TX.

Wireless power transfer

But power, as well as data, crosses the floor for recharging of batteries by *Inductive Power Transfer (IPT)* for the equipment above the floor. The AGV does not have to be at a charging point.

It can charge while moving along a power line and only draw on the battery when away from such a line.

Their demonstration system transfers up to 250W to an AGV or robot, barely enough to power two incandescent light bulbs. By comparison, the HOPPECKE connected charger supplies 4.56kW to an AGV, or 18 times more.

What we expect from a floor

Seeing this demonstration makes you reflect on what to expect from a floor, and intelligence is generally not in the list. We take floors for granted and only notice when they malfunction.

For example, dragging a wheeled suitcase on the tiled across Dallas Fort-Worth airport’s terminal C physically draws your attention to the way tile boundaries shake your wheeled suitcase.

Floor requirements by function

In Manufacturing the requirements on the floors vary by location:

– The transportation aisles need smooth, horizontal surfaces, free of edges, cracks or potholes that interfere with the traffic of carts, tugger trains, pallet jacks, or forklifts.

– The machines need a foundation that doesn’t subside or tilt under their weight or as a result of vibrations.

– Production work areas need floor coverings with cushioning for operators to stand on all day.

– …

Issues with painted signage

Painting signs on the floor is problematic because traffic erases arrows, dashed lines and numbers. One solution recently adopted by Ikea in its showrooms is to project arrows of light from above onto the concrete floor. These markings do not wear down no matter how many people walk over them.

Can a smart floor meet these expectations?

Intelligence is not among these expectations, and the smart floor is an unexpected idea.

The one at ARENA2036 only supports light equipment and assembly of small products. It couldn’t hold a stamping press or a lathe. You could place it around heavy machines, on top of the concrete floor holding them, but it seems doubtful that the plexiglass sheets we saw could hold the weight of carts carrying dies or stacks of metal sheets going into auto bodies. It’s not clear either how one could adapt the concept to process industries.

Conclusions

We went to visit Industry 4.0 leaders in search of technology that is or can be useful in improving the actual factories with which we work. Many run processes that don’t meet the necessary conditions for the smart floor we saw to operate, and the economic justification is not ovious for the ones that do meet these conditions.

Even within Bosch, it’s an R&D project, not deployed in any factory. Still, in this form or another, it may indeed become part of factories of the future if engineers find compelling applications. It took decades for this to happen with barcode systems and with pick-to-light. Smart floors may turn out this way as well.

August 14, 2019 @ 1:29 pm

You visited “a research facility called ARENA2036, attached to the University of Stuttgart”. What is the ETA for this technology to actually become commercially viable like the KIVA robots in Amazon’s distribution centers or the Takoaka II assembly line ?

August 15, 2019 @ 8:11 pm

This is R&D, and doesn’t claim to be anything else. If we go by the name of the facility, it should be operational by 2036… Some of the other systems we saw demonstrated at ARENA2036 looked like viable products, like, for example, the Drag & Bot universal robot training system or the pick confirmation bracelets from ThingOS for Pick-to-Light.

September 25, 2019 @ 1:02 pm

This seems like the it can be highly beneficial to warehouses and distribution centers. Eliminating wires and hoses will improve the safety and efficiency of the users. Along with the movement of materials will decrease man power needed and improve the organization of the materials.

September 25, 2019 @ 1:32 pm

Although these Smart Floors are not in use yet, do you think that this will significantly impact the supply chain process for the better in years to come?