Aug 15 2013

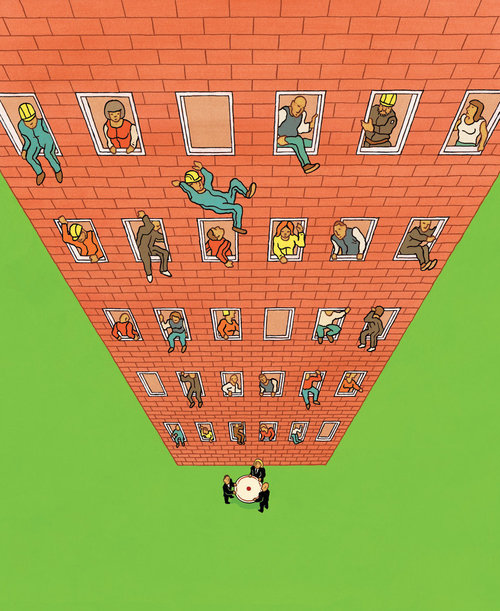

Don’t ‘Lean’ on Me, Hospital Workers Say | Labor Notes

See on Scoop.it – lean manufacturing

One popular suggestion: replace a sticky combination lock with swipe-card entry. But that would cost too much.

Instead, on a consultant’s recommendation, supplies were rearranged. Blue masking tape outlines now show where each item is supposed to go. A sign lists the “five S’s” of workplace organization (sorting, straightening, cleaning (shine), standardizing, and service). Each shift, one nurse is supposed to check them off.”

– See more at: http://www.labornotes.org/2013/06/dont-lean-me-hospital-workers-say#sthash.BUCnk306.dpuf

I had seen articles bashing Lean from a union perspective in manufacturing, but this is the first one I see about hospitals.

On the one hand, the author thinks that the work processes cannot be improved, and that the only way outcomes can be is by new equipment or more people. On the other hand, the “improvements” she describes are definitely L.A.M.E. (Lean As Mistakenly Implemented) rather than Lean: 5S as the most visible change, curtailment of communications between outgoing and incoming nurses as shift change, or reduction in the skill level of heart monitor operators, etc.

If that is what “Lean Health Care” boils down to, she has a point. But what about the use of Kanbans to manage supplies, as described in the “Par versus Kanban” article I scooped on 8/13?

See on www.labornotes.org

Dec 23 2013

Pinnacle Misses the Mark with Lean Manufacturing | Gunther W. Anderson | Iowa Labor News

See on Scoop.it – lean manufacturing

“…There is a difference between lean manufacturing and just plain cutting corners. Pinnacle is attempting to achieve a similar end result (increased profits and productivity) without investing the time, effort, and resources necessary to achieve those results through true lean manufacturing practices, and they are doing so at the expense of their workforce…”

This union member’s criticism of his company’s implementation of Lean is remarkable for being so constructive. He does not dismiss Lean Manufacturing as just another ploy by management to squeeze more out the workers.

Instead, he blames his company’s management for being Lean in name only. He quotes Mike Thelen and David Meier on what Lean is supposed to be, and contrasts it with what the company actually does.

Not having heard management’s side of the story, I have no idea of the extent to which his points are valid. The tone of the article, however, shows the author as a thinking man who wants to improve the way he works, exactly the kind of people you want around when genuinely implementing Lean.

See on iowalabornews.com

Share this:

Like this:

By Michel Baudin • Press clippings • 3 • Tags: LAME, Lean, LINO, Union